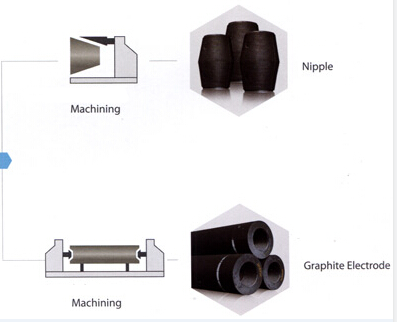

Graphite Electrodes Production Process

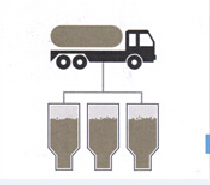

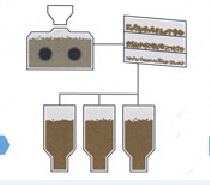

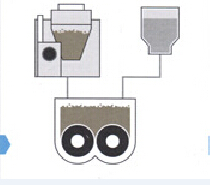

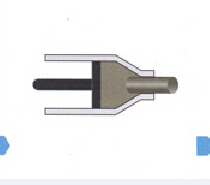

1.Raw Materials HP GRAPHITE takes the high-quality needle calcined coke as the production materials of graphite electrode. | 2.Intermediate Crushing & Sieving The needle coke is crushed in the mechanical equipment and sieved, and then, subjected to the burdening proportionally according to the formula. | 3.Kneading The raw materials subjected to the burdening are heated and kneaded together with a certain proportion of pitch, to prepare the plastic thickener. | 4.Profiling The kneaded thickener is pressed after cooling to the process temperature, and subjected to the compression molding according to the product requirement and specification. |

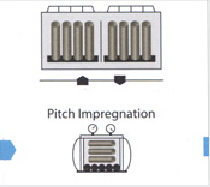

| 5.Calcination In the calciner, the "green" electrode is calcined to the specified temperature according to the process requirement, and the calcined products are impregnated with the special impregnating pitch according to the specific process, to improve the density and mechanical strength of the products; and then, the impregnated products are repeatedly calcined to improve the product performance. | 6.Graphitization The products calcined twice are powered on in the electric resistance furnace for graphitization for heating up to 3000℃, so that the carbon atom structure is rearranged into the specific crystalline form, and the carbon is converted to the graphite. |

| |