Related Reading

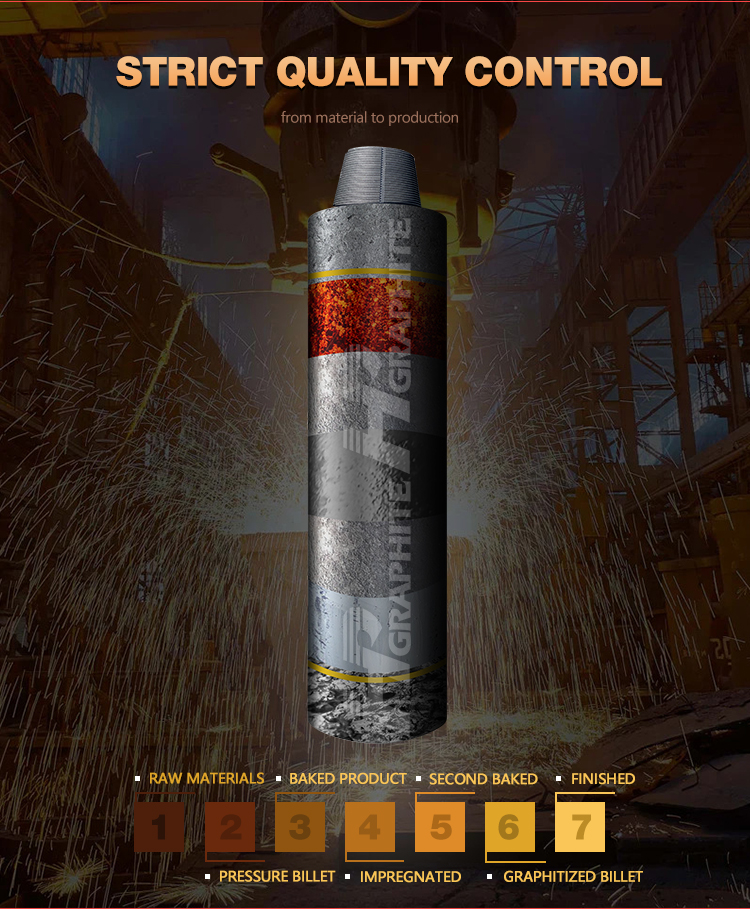

Graphite electrode producted of petroleum coke combined with pitch after calcination, through molding, baking, impregnation and graphitization.

Physical & Chemical Index

ITEMS | REGULAR POWER | HIGH POWER | ULTRA HIGH POWER | ||||

Ø75-200 | Ø250-600 | Ø200-400 | Ø450-600 | Ø200-500 | Ø550-700 | ||

Resistance μΩ.m (Max) | Electrode | 8.5 | 6.5 | 5.5 | |||

Nipple | 6.5 | 5.5 | 4.5 | ||||

Density g/cm³ (min) | Electrode | 1.6 | 1.58 | 1.68 | 1.65 | 1.68 | 1.7 |

Nipple | 1.75 | 1.78 | 1.8 | ||||

Flexure Strength Mpa (min) | Electrode | 10.0 | 8.0 | 10.5 | 9.8 | 11.0 | |

Nipple | 15.0 | 17.0 | 20.0 | ||||

Elastic Modulus Gpa (max) | Electrode | 9.3 | 14.0 | 14.0 | |||

Nipple | 14.0 | 16.0 | 22.0 | ||||

Ash Content | Electrode | 0.1 | 0.1 | 0.1 | |||

Nipple | 0.1 | 0.1 | 0.1 | ||||

CTE (100-600℃) | Electrode | 2.9 | 2.4 | 1.5 | |||

Nipple | 2.7 | 2.2 | 1.4 | ||||

Current Load

NOMINAL DIAMETER |

REGULAR POWER |

HIGH POWER |

ULTRA HIGH POWER | |||

MM | Current Load (A) | Current Density (A/cm²) | Current Load (A) | Current Density (A/cm²) | Current Load (A) | Current Density (A/cm²) |

75 | 1000-1400 | 22-31 |

|

|

|

|

100 | 1500-2400 | 19-30 |

|

|

|

|

130 | 2200-3400 | 17-26 |

|

|

|

|

150 | 3000-4500 | 16-25 |

|

|

|

|

200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 |

|

|

250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-30 |

500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

550 | 28000-34000 | 12-14 | 34000-53000 | 14-22 | 45000-65000 | 18-27 |

600 | 30000-36000 | 11-13 | 38000-58000 | 13-21 | 50000-75000 | 18-26 |

650 | 32000-39000 | 10-12 | 41000-65000 | 12-20 | 60000-85000 | 18-25 |

700 | 34000-42000 | 9-11 | 45000-72000 | 12-19 | 70000-120000 | 18-30 |

Surface Quality

1、There are no more than two defects or holes on the surface of the electrode and the size shall not exceed the value in the following table. |

SPECIFICATION SIZE | NOMINAL DIAMETER OF GRAPHITE ELECTRODE (MM) | ||

75-225 | 250-400 | 450-800 | |

Diameter(mm) | 10-20 | 20-30 | 30-40 |

Depth(mm) | 3-5 | 5-10 | 10-15 |

Graphite Electrode Size & Tolerance

DIAMETER (MM) | LENGTH (MM) | ||||||

Nominal Diameter | Actual Diameter |

Nominal Length |

Tolerance |

Short Length | |||

Inch | mm | Max | Min | Rough spot | |||

3 | 75 | 78 | 73 | 72 | 1000/1200/1400/1600 |

±100 |

-275 |

4 | 100 | 103 | 98 | 97 | 1000/1200/1400/1600 | ||

5 | 130 | 132 | 127 | 126 | 1000/1200/1400/1600 | ||

6 | 150 | 154 | 149 | 146 | 1200/1400/1600/1800 | ||

7 | 175 | 179 | 174 | 171 | 1200/1400/1600/1800 | ||

8 | 200 | 205 | 200 | 197 | 1600/1800 | ||

9 | 225 | 230 | 225 | 222 | 1600/1800 | ||

10 | 250 | 256 | 251 | 248 | 1600/1800/2000 | ||

12 | 300 | 307 | 302 | 299 | 1600/1800/2000/2200 | ||

14 | 350 | 358 | 352 | 349 | 1600/1800/2000/2200 | ||

16 | 400 | 409 | 403 | 400 | 1600/1800/2000/2200 | ||

18 | 450 | 460 | 454 | 451 | 1600/1800/2000/2200 | ||

20 | 500 | 511 | 505 | 502 | 1800/2000/2200/2400 | ||

22 | 550 | 562 | 556 | 553 | 1800/2000/2200/2400 | ||

24 | 600 | 613 | 607 | 604 | 2000/2200/2400/2700 | ||

26 | 650 | 663 | 659 | 656 | 2400/2700 | ||

28 | 700 | 714 | 710 | 707 | 2400/2700 | ||

Coupling Torque Reference For Nipple & Electrode

ELECTRODE DIAMETER | Inch | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

mm | 200 | 225 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

BREAKAWAY TORQUE | n.m | 200 | 300 | 400 | 550 | 800 | 900 | 1100 | 1500 | 1900 | 2400 |

Physical & Chemical Index

ITEMS | REGULAR POWER | HIGH POWER | ULTRA HIGH POWER | ||||

Ø75-200 | Ø250-600 | Ø200-400 | Ø450-600 | Ø200-500 | Ø550-700 | ||

Resistance μΩ.m (Max) | Electrode | 8.5 | 6.5 | 5.5 | |||

Nipple | 6.5 | 5.5 | 4.5 | ||||

Density g/cm³ (min) | Electrode | 1.6 | 1.58 | 1.68 | 1.65 | 1.68 | 1.7 |

Nipple | 1.75 | 1.78 | 1.8 | ||||

Flexure Strength Mpa (min) | Electrode | 10.0 | 8.0 | 10.5 | 9.8 | 11.0 | |

Nipple | 15.0 | 17.0 | 20.0 | ||||

Elastic Modulus Gpa (max) | Electrode | 9.3 | 14.0 | 14.0 | |||

Nipple | 14.0 | 16.0 | 22.0 | ||||

Ash Content | Electrode | 0.1 | 0.1 | 0.1 | |||

Nipple | 0.1 | 0.1 | 0.1 | ||||

CTE (100-600℃) | Electrode | 2.9 | 2.4 | 1.5 | |||

Nipple | 2.7 | 2.2 | 1.4 | ||||

Current Load

NOMINAL DIAMETER |

REGULAR POWER |

HIGH POWER |

ULTRA HIGH POWER | |||

MM | Current Load (A) | Current Density (A/cm²) | Current Load (A) | Current Density (A/cm²) | Current Load (A) | Current Density (A/cm²) |

75 | 1000-1400 | 22-31 |

|

|

|

|

100 | 1500-2400 | 19-30 |

|

|

|

|

130 | 2200-3400 | 17-26 |

|

|

|

|

150 | 3000-4500 | 16-25 |

|

|

|

|

200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 |

|

|

250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-30 |

500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

550 | 28000-34000 | 12-14 | 34000-53000 | 14-22 | 45000-65000 | 18-27 |

600 | 30000-36000 | 11-13 | 38000-58000 | 13-21 | 50000-75000 | 18-26 |

650 | 32000-39000 | 10-12 | 41000-65000 | 12-20 | 60000-85000 | 18-25 |

700 | 34000-42000 | 9-11 | 45000-72000 | 12-19 | 70000-120000 | 18-30 |

Surface Quality

1、There are no more than two defects or holes on the surface of the electrode and the size shall not exceed the value in the following table. |

SPECIFICATION SIZE | NOMINAL DIAMETER OF GRAPHITE ELECTRODE (MM) | ||

75-225 | 250-400 | 450-800 | |

Diameter(mm) | 10-20 | 20-30 | 30-40 |

Depth(mm) | 3-5 | 5-10 | 10-15 |

Graphite Electrode Size & Tolerance

DIAMETER (MM) | LENGTH (MM) | ||||||

Nominal Diameter | Actual Diameter |

Nominal Length |

Tolerance |

Short Length | |||

Inch | mm | Max | Min | Rough spot | |||

3 | 75 | 78 | 73 | 72 | 1000/1200/1400/1600 |

±100 |

-275 |

4 | 100 | 103 | 98 | 97 | 1000/1200/1400/1600 | ||

5 | 130 | 132 | 127 | 126 | 1000/1200/1400/1600 | ||

6 | 150 | 154 | 149 | 146 | 1200/1400/1600/1800 | ||

7 | 175 | 179 | 174 | 171 | 1200/1400/1600/1800 | ||

8 | 200 | 205 | 200 | 197 | 1600/1800 | ||

9 | 225 | 230 | 225 | 222 | 1600/1800 | ||

10 | 250 | 256 | 251 | 248 | 1600/1800/2000 | ||

12 | 300 | 307 | 302 | 299 | 1600/1800/2000/2200 | ||

14 | 350 | 358 | 352 | 349 | 1600/1800/2000/2200 | ||

16 | 400 | 409 | 403 | 400 | 1600/1800/2000/2200 | ||

18 | 450 | 460 | 454 | 451 | 1600/1800/2000/2200 | ||

20 | 500 | 511 | 505 | 502 | 1800/2000/2200/2400 | ||

22 | 550 | 562 | 556 | 553 | 1800/2000/2200/2400 | ||

24 | 600 | 613 | 607 | 604 | 2000/2200/2400/2700 | ||

26 | 650 | 663 | 659 | 656 | 2400/2700 | ||

28 | 700 | 714 | 710 | 707 | 2400/2700 | ||

Coupling Torque Reference For Nipple & Electrode

ELECTRODE DIAMETER | Inch | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

mm | 200 | 225 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

BREAKAWAY TORQUE | n.m | 200 | 300 | 400 | 550 | 800 | 900 | 1100 | 1500 | 1900 | 2400 |

Physical & Chemical Index

ITEMS | REGULAR POWER | HIGH POWER | ULTRA HIGH POWER | ||||

Ø75-200 | Ø250-600 | Ø200-400 | Ø450-600 | Ø200-500 | Ø550-700 | ||

Resistance μΩ.m (Max) | Electrode | 8.5 | 6.5 | 5.5 | |||

Nipple | 6.5 | 5.5 | 4.5 | ||||

Density g/cm³ (min) | Electrode | 1.6 | 1.58 | 1.68 | 1.65 | 1.68 | 1.7 |

Nipple | 1.75 | 1.78 | 1.8 | ||||

Flexure Strength Mpa (min) | Electrode | 10.0 | 8.0 | 10.5 | 9.8 | 11.0 | |

Nipple | 15.0 | 17.0 | 20.0 | ||||

Elastic Modulus Gpa (max) | Electrode | 9.3 | 14.0 | 14.0 | |||

Nipple | 14.0 | 16.0 | 22.0 | ||||

Ash Content | Electrode | 0.1 | 0.1 | 0.1 | |||

Nipple | 0.1 | 0.1 | 0.1 | ||||

CTE (100-600℃) | Electrode | 2.9 | 2.4 | 1.5 | |||

Nipple | 2.7 | 2.2 | 1.4 | ||||

Current Load

NOMINAL DIAMETER |

REGULAR POWER |

HIGH POWER |

ULTRA HIGH POWER | |||

MM | Current Load (A) | Current Density (A/cm²) | Current Load (A) | Current Density (A/cm²) | Current Load (A) | Current Density (A/cm²) |

75 | 1000-1400 | 22-31 |

|

|

|

|

100 | 1500-2400 | 19-30 |

|

|

|

|

130 | 2200-3400 | 17-26 |

|

|

|

|

150 | 3000-4500 | 16-25 |

|

|

|

|

200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 |

|

|

250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-30 |

500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

550 | 28000-34000 | 12-14 | 34000-53000 | 14-22 | 45000-65000 | 18-27 |

600 | 30000-36000 | 11-13 | 38000-58000 | 13-21 | 50000-75000 | 18-26 |

650 | 32000-39000 | 10-12 | 41000-65000 | 12-20 | 60000-85000 | 18-25 |

700 | 34000-42000 | 9-11 | 45000-72000 | 12-19 | 70000-120000 | 18-30 |

Surface Quality

1、There are no more than two defects or holes on the surface of the electrode and the size shall not exceed the value in the following table. |

SPECIFICATION SIZE | NOMINAL DIAMETER OF GRAPHITE ELECTRODE (MM) | ||

75-225 | 250-400 | 450-800 | |

Diameter(mm) | 10-20 | 20-30 | 30-40 |

Depth(mm) | 3-5 | 5-10 | 10-15 |

Graphite Electrode Size & Tolerance

DIAMETER (MM) | LENGTH (MM) | ||||||

Nominal Diameter | Actual Diameter |

Nominal Length |

Tolerance |

Short Length | |||

Inch | mm | Max | Min | Rough spot | |||

3 | 75 | 78 | 73 | 72 | 1000/1200/1400/1600 |

±100 |

-275 |

4 | 100 | 103 | 98 | 97 | 1000/1200/1400/1600 | ||

5 | 130 | 132 | 127 | 126 | 1000/1200/1400/1600 | ||

6 | 150 | 154 | 149 | 146 | 1200/1400/1600/1800 | ||

7 | 175 | 179 | 174 | 171 | 1200/1400/1600/1800 | ||

8 | 200 | 205 | 200 | 197 | 1600/1800 | ||

9 | 225 | 230 | 225 | 222 | 1600/1800 | ||

10 | 250 | 256 | 251 | 248 | 1600/1800/2000 | ||

12 | 300 | 307 | 302 | 299 | 1600/1800/2000/2200 | ||

14 | 350 | 358 | 352 | 349 | 1600/1800/2000/2200 | ||

16 | 400 | 409 | 403 | 400 | 1600/1800/2000/2200 | ||

18 | 450 | 460 | 454 | 451 | 1600/1800/2000/2200 | ||

20 | 500 | 511 | 505 | 502 | 1800/2000/2200/2400 | ||

22 | 550 | 562 | 556 | 553 | 1800/2000/2200/2400 | ||

24 | 600 | 613 | 607 | 604 | 2000/2200/2400/2700 | ||

26 | 650 | 663 | 659 | 656 | 2400/2700 | ||

28 | 700 | 714 | 710 | 707 | 2400/2700 | ||

Coupling Torque Reference For Nipple & Electrode

ELECTRODE DIAMETER |

Inch | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

mm | 200 | 225 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |

BREAKAWAY TORQUE | n.m | 200 | 300 | 400 | 550 | 800 | 900 | 1100 | 1500 | 1900 | 2400 |

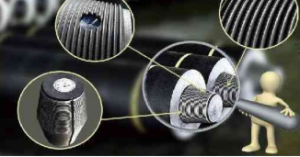

Graphite electrode nipple (RP,HP, UHP);Auxiliary

Graphite electrode nipple is fitting for graphite electrode. Graphite electrode generally has higher requirements for nipple, which has a special production process, can be divided into (regular power graphite electrode nipple, high power graphite electrode nipple, and ultra high power graphite electrode nipple).

In order to prevent the connection of graphite electrode from loosening, all graphite electrode nipples produced by HP Graphite Co., Ltd. have been specially processed. The specifications of conical graphite electrode nipple (Japanese nipple) refer to the figure below.

![]() Detailed parameter of 3TPI NIPPLE

Detailed parameter of 3TPI NIPPLE

NOMINAL DIAMETER | NIPPLE | SOCKET | PITCH | |||||||||

D | L | d2 | I | d1 | H | |||||||

200 | 122.24 |

0-0.50 | 177.80 |

0-1 | 80.00 |

0-5 |

<7 | 115.92 |

+0.500 | 94.90 |

+70 |

6.35 |

225 | 139.70 | 177.80 | 97.46 | 133.38 | 94.90 | |||||||

250 | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | |||||||

300 | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | |||||||

350 | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | |||||||

400 | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | |||||||

400 | 222.25 | 335.60 | 150.00 | 215.93 | 183.80 | |||||||

450 | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | |||||||

450 | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | |||||||

500 | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | |||||||

500 | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | |||||||

550 | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | |||||||

550 | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | |||||||

600 | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | |||||||

600 | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | |||||||

650 | 355.60 | 457.20 | 266.79 | 349.28 | 234.60 | |||||||

650 | 355.60 | 558.80 | 249.86 | 349.28 | 285.40 | |||||||

700 | 374.65 | 457.20 | 285.84 | 368.33 | 234.60 | |||||||

700 | 374.65 | 558.80 | 268.91 | 368.33 | 285.40 | |||||||

Detailed parameter of 4TPI NIPPLE

NOMINAL DIAMETER | NIPPLE | SOCKET | PITCH | |||||||||

D | L | d2 | I | d1 | H | |||||||

225 | 139.70 |

0-0.50 | 203.20 |

0-1 | 90.73 |

0-5 |

<10 | 131.27 |

+0.500 | 107.60 |

+70 |

8.47 |

250 | 155.57 | 220.00 | 103.80 | 147.14 | 116.00 | |||||||

300 | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | |||||||

350 | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | |||||||

400 | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | |||||||

400 | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | |||||||

450 | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | |||||||

450 | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | |||||||

500 | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | |||||||

500 | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | |||||||

550 | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | |||||||

Focus on service, pay attention to in the process of using products, help customers to solve the problem.

Strict Quality Control System

From raw materials to products, we strictly monitor the quality of production, directly remove

unqualified products to eliminate your worries.

Material Selection Principle

"Quality First, Price Second": We have 19 years industry experience, numerous material suppliers and partners to ensure the quality of raw materials and proper prices.

Well-developed Sales Solution

We have free customer consultation service to provide optimal solution for customers.

After-sales Service

HP Graphite Co., Ltd. will provide free installation & adjustment for the first-time customers, and provide solutions within 48 hours.

Emergency Solutions

HP Graphite Co., Ltd. provides emergency solutions after the accident and takes necessary measures to provide assistance according to the situation.

Graphite Crucibles

Graphite Blocks

Graphite Columns

If you have any questions about graphite products, submit the form below to us or you can also contact us directly.

If you have any questions about graphite products, submit the form below to us or you can also contact us directly.

Submit your demand and we will reply to you within 12 hours.

Can I help You?