Steelmaking

【Graphite Electrodes】Intensifying Domestic Competition and External Pressure, Leading ...

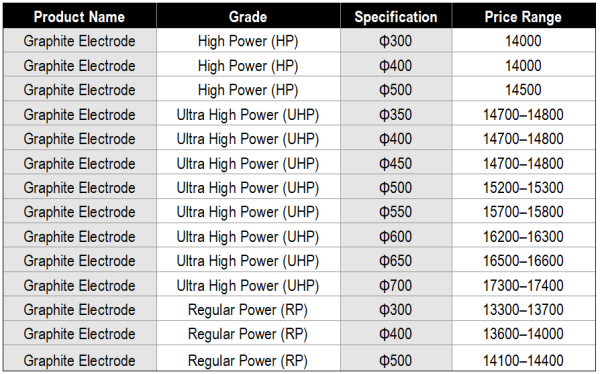

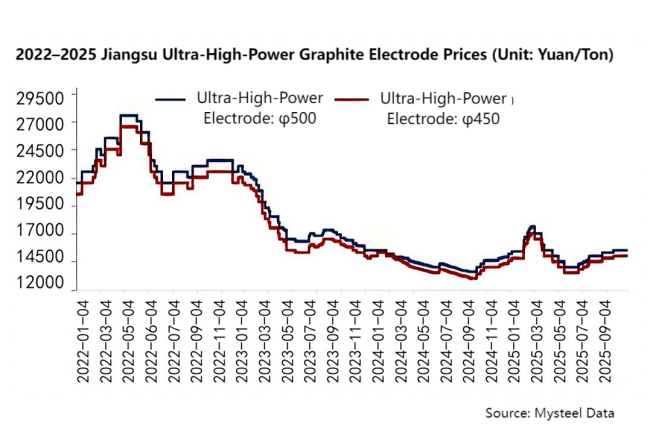

【Graphite Electrodes】Intensifying Domestic Competition and External Pressure, Leading Enterprises Still Hold the "Steering Wheel" of Pricing Recently, China's ultra-high power (UHP) graphite electrode market has continued to operate in a stable manner. According to survey data from the Lianye Materials platform, the current mainstream ex-factory price (including tax) for Φ... ...

【Carbon】From Carbon Products to the Development of the Carbon Industry

【Carbon】From Carbon Products to the Development of the Carbon IndustryOverview of Carbon DevelopmentHuman use of carbon has evolved alongside human development. In ancient times, humans began using carbon (charcoal) when they discovered and harnessed fire. In China, the Geography of the Former Han recorded, "Yuzhang Commandery produces stones that can burn as firewood," referr... ...

【Graphite Electrode】 Forecast for China's UHP Graphite Electrode Market in November

【Graphite Electrode】 Forecast for China's UHP Graphite Electrode Market in November In October, China's ultra-high power (UHP) graphite electrode market first remained stable and then showed a slight increase. Steel mill bidding prices rose modestly. Due to pre-holiday stockpiling, adjustments in steelmaking processes, and declining finished steel profits, transaction ... ...

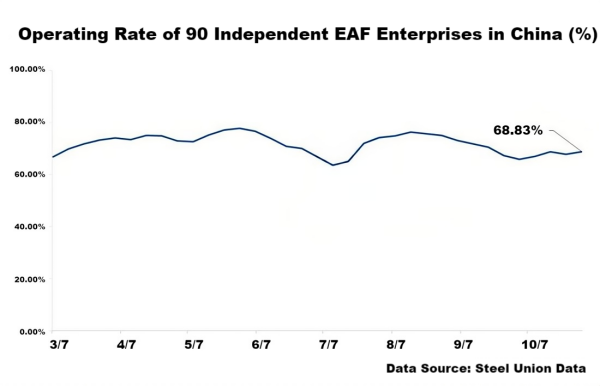

【EAF Steel】Survey and Statistics on Independent Electric Arc Furnace Production in China

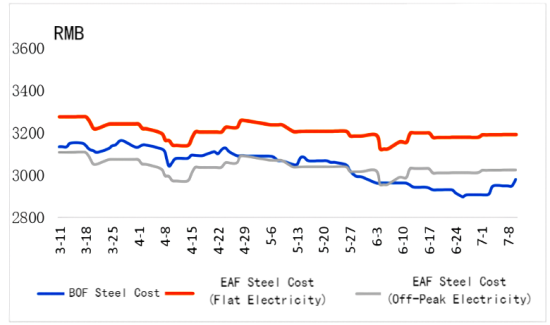

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality. 【Electric Arc Furnace Steel】Survey and Statistics on Independent Electric A... ...

【Hebei】Blast Furnaces Below 1,000 m³ and General Steel Converters Below 100 Tons Fully Phased Out

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Hebei】Blast Furnaces Below 1,000 m³ and General Steel Converters Below 100 Tons Ful... ...

【Steel Market】September Observation: Manufacturing Supports, Construction Weak,...

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel Market】September Observation: Manufacturing Supports, Construction Weak, High... ...

【Electrode】Growth Rate 5.2%! Trend Analysis of Carbon Electrode Market...

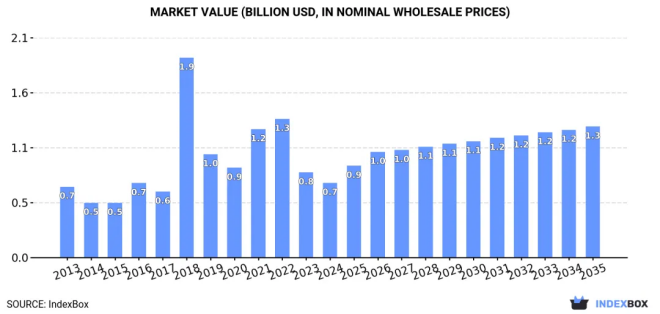

【Electrode】Growth Rate 5.2%! Trend Analysis of the Carbon Electrode Marketin the Middle East and North Africa The demand for carbon electrodes in the Middle East and North Africa (MENA) is steadily increasing, and consumption is expected to show a positive trend over the next decade. Market performance is predicted to slightly slow down, with a compound annual growth rate (CAGR... ...

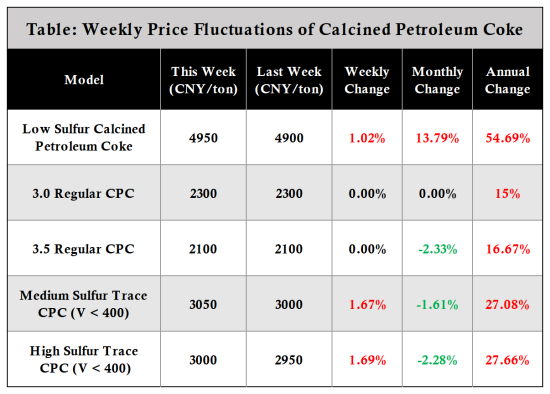

【Calcined Petroleum Coke】Price Hiked by 100 Yuan! Market Prices Rise Across the Board ...

【Calcined Petroleum Coke】Price Hiked by 100 Yuan! Market Prices Rise Across the Board This Week, Downstream Stockpiling Intentions Strengthen Weekly Price Trend Analysis of Calcined Petroleum CokeThis week (July 18–24, 2025), the domestic calcined petroleum coke (CPC) market witnessed moderate trading activity. Supported by favorable raw material prices, the prices of various... ...

【Steel Market】Weekly Observation: Sentiment Rebounding, Negative Feedback Delayed

Graphite electrodes are vital consumables in EAF steelmaking, mainly used for arc heating. With superior electrical conductivity and high-temperature resistance, they are key to improving both the output and quality of EAF steel.【Steel Market】Weekly Observation: Sentiment Rebounding, Negative Feedback Delayed Last week, policies aimed at "curbing internal competition" continued... ...

【Electric Arc Furnace Steel】Anti-Overcompetition Sentiment Drives Output Stabilization

Graphite electrodes are key consumables in EAF steelmaking, ensuring efficiency and quality with high conductivity and heat resistance.【Electric Arc Furnace Steel】Anti-Overcompetition Sentiment Drives Output StabilizationDue to high temperatures and heavy rainfall, construction activities in many regions of China were hindered this week, leading to a further decline in demand f... ...

【Graphite Electrodes】Intensifying Domestic Competition and External Pressure, Leading ...

【Graphite Electrodes】Intensifying Domestic Competition and External Pressure, Leading Enterprises Still Hold the "Steering Wheel" of Pricing Recently, China's ultra-high power (UHP) graphite electrode market has continued to operate in a stable manner. According to survey data from the Lianye Materials platform, the current mainstream ex-factory price (including tax) for Φ... ...

【Carbon】From Carbon Products to the Development of the Carbon Industry

【Carbon】From Carbon Products to the Development of the Carbon IndustryOverview of Carbon DevelopmentHuman use of carbon has evolved alongside human development. In ancient times, humans began using carbon (charcoal) when they discovered and harnessed fire. In China, the Geography of the Former Han recorded, "Yuzhang Commandery produces stones that can burn as firewood," referr... ...

【Graphite Electrode】 Forecast for China's UHP Graphite Electrode Market in November

【Graphite Electrode】 Forecast for China's UHP Graphite Electrode Market in November In October, China's ultra-high power (UHP) graphite electrode market first remained stable and then showed a slight increase. Steel mill bidding prices rose modestly. Due to pre-holiday stockpiling, adjustments in steelmaking processes, and declining finished steel profits, transaction ... ...

【EAF Steel】Survey and Statistics on Independent Electric Arc Furnace Production in China

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality. 【Electric Arc Furnace Steel】Survey and Statistics on Independent Electric A... ...

【Hebei】Blast Furnaces Below 1,000 m³ and General Steel Converters Below 100 Tons Fully Phased Out

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Hebei】Blast Furnaces Below 1,000 m³ and General Steel Converters Below 100 Tons Ful... ...

【Steel Market】September Observation: Manufacturing Supports, Construction Weak,...

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel Market】September Observation: Manufacturing Supports, Construction Weak, High... ...

【Electrode】Growth Rate 5.2%! Trend Analysis of Carbon Electrode Market...

【Electrode】Growth Rate 5.2%! Trend Analysis of the Carbon Electrode Marketin the Middle East and North Africa The demand for carbon electrodes in the Middle East and North Africa (MENA) is steadily increasing, and consumption is expected to show a positive trend over the next decade. Market performance is predicted to slightly slow down, with a compound annual growth rate (CAGR... ...

【Calcined Petroleum Coke】Price Hiked by 100 Yuan! Market Prices Rise Across the Board ...

【Calcined Petroleum Coke】Price Hiked by 100 Yuan! Market Prices Rise Across the Board This Week, Downstream Stockpiling Intentions Strengthen Weekly Price Trend Analysis of Calcined Petroleum CokeThis week (July 18–24, 2025), the domestic calcined petroleum coke (CPC) market witnessed moderate trading activity. Supported by favorable raw material prices, the prices of various... ...

【Steel Market】Weekly Observation: Sentiment Rebounding, Negative Feedback Delayed

Graphite electrodes are vital consumables in EAF steelmaking, mainly used for arc heating. With superior electrical conductivity and high-temperature resistance, they are key to improving both the output and quality of EAF steel.【Steel Market】Weekly Observation: Sentiment Rebounding, Negative Feedback Delayed Last week, policies aimed at "curbing internal competition" continued... ...

【Electric Arc Furnace Steel】Anti-Overcompetition Sentiment Drives Output Stabilization

Graphite electrodes are key consumables in EAF steelmaking, ensuring efficiency and quality with high conductivity and heat resistance.【Electric Arc Furnace Steel】Anti-Overcompetition Sentiment Drives Output StabilizationDue to high temperatures and heavy rainfall, construction activities in many regions of China were hindered this week, leading to a further decline in demand f... ...