What is the difference between graphite crucible and quartz crucible?

What is the difference between graphite crucible and quartz crucible?

"In the blast furnace fire, the crucible is fully refined"

How is the crucible made?

The raw materials for crucible production can be summarized into three types. The first is crystalline natural graphite, the second is plastic refractory clay, and the third is calcined hard kaolin skeleton clinker.

In order to meet the requirements of customers to purchase more durable, such as: silicon carbide, alumina, emery and iron silicon as the skeleton clinker crucible. This clinker has a significant effect on improving the product quality of crucible and enhancing the density and mechanical strength of crucible.

So what is the crucible used in industry?

Crucible is used for melting and smelting metal liquid, or a refractory container of material chemical reaction, by heating the crucible can melt or extract some needed substances, is also an important tool for chemical reaction of some substances through heating.

How do we choose the type of crucible according to the production needs?

Crucibles can withstand high temperature. Crucibles of different materials can be selected according to different properties and service temperatures of molten corrosion objects.

Iron crucible

In the melting of NaOH and other strong alkaline substances will use iron crucible, but due to rust and oxidation and other problems, is not widely used, and it is still dominated by inactive metal crucible.

Cast iron crucible

Cast iron crucible is cast from pig iron, used for melting aluminum alloy, zinc alloy, lead alloy, tin alloy, antimony alloy and other metal dishes, more durable than iron crucible.

Quartz crucible

Quartz crucible can be used below 1650 degrees. It can be divided into transparent and opaque. It is usually used for precision manufacturing.

Corundum crucible

The alumina content is more than 95%, which is hard and resistant to melting. It is suitable for some weak alkaline substances to be used in flux melting sample experiment.

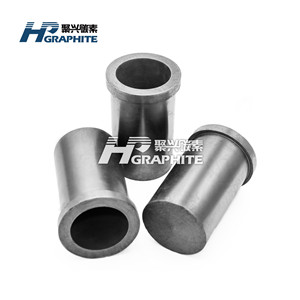

Graphite crucible

The main raw material is crystalline natural graphite, which has good thermal conductivity and high temperature resistance. In the process of high temperature use, the coefficient of thermal expansion is small, and it has certain strain resistance to rapid heating and cooling. It has strong corrosion resistance to acid and alkaline solutions and excellent chemical stability. Because of the above excellent properties, it is widely used in the smelting of alloy tool steel and the smelting of non-ferrous metals and their alloys in metallurgy, casting, machinery, chemical industry and other industrial departments, and has good technical and economic effects.

Silicon carbide crucible

The evolved version of graphite crucible has better performance and longer service life than graphite crucible, but the price is more expensive than graphite crucible.

Graphite crucibles and quartz crucibles are the most widely used in the precious metal industry,

Graphite crucible is an inorganic non-metallic material with excellent performance, which has the characteristics of good lubricity, thermal conductivity and high temperature resistance.

What's the difference between graphite crucible and quartz crucible?

01 color

The graphite crucible is black and the quartz crucible is white.

02 heating mode

There is resistance in graphite

(1) When the high-frequency current passes through, the graphite crucible heats the metal material through its own induction heating.

(2) Smelting range: copper, gold, K gold, silver, alloy, etc.

Quartz has no resistance

(1) When the medium frequency current passes through, the metal material in the quartz crucible generates induction heating.

(2) Quartz crucible does not generate heat. It is suitable for smelting: gold, palladium, stainless steel, gold, iron, aluminum, etc.

03 melting

Graphite crucible

It can be used for the melting of more kinds and less quantities of alloys. When we need to change the type of alloy, we just need to exchange the graphite crucible.

Quartz crucible

If the melting temperature exceeds 1800 ℃, sodium thiosulfate (dried at 212 ℃) and potassium bisulfate (sodium) can be used as flux.

Quartz crucible is more resistant to high temperature than graphite crucible, get the technical news from us.

No related results found

0 Replies