Construction steel

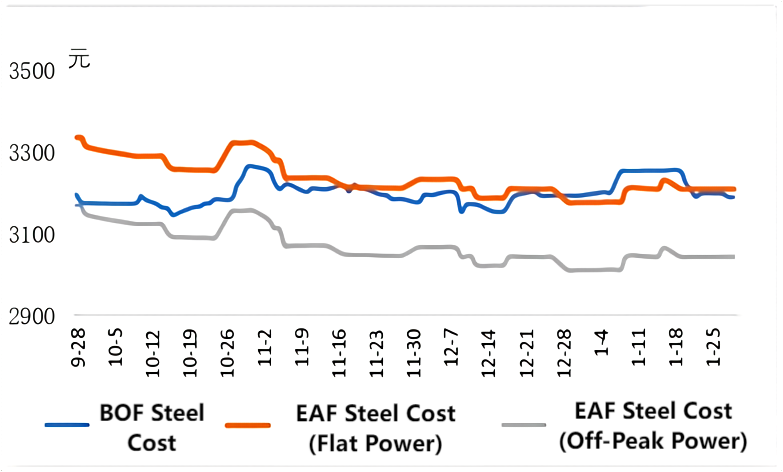

【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills This... ...

【EAF Steel】Demand Remains Weak, Output Edges Down

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】Demand Remains Weak, Output Edges Down This week, China's con... ...

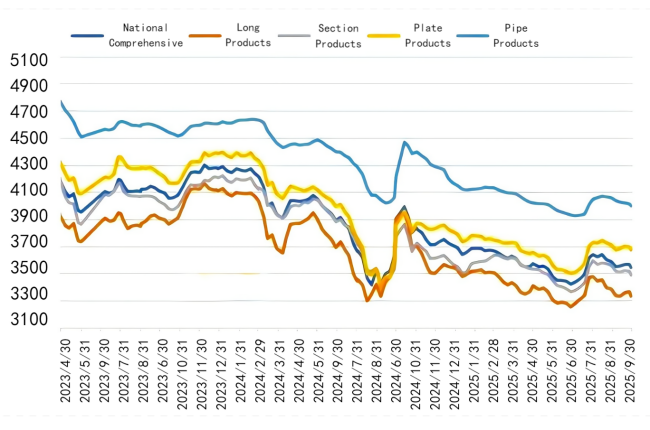

【Steel Market Watch】Are Steel Prices Still Salvageable at Year-End?

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel Market Watch】Are Steel Prices Still Salvageable at Year-End? On December 8, ... ...

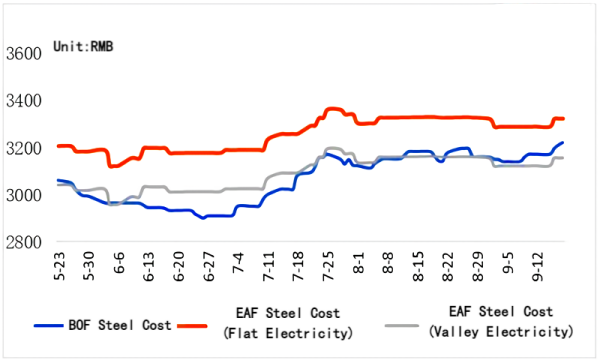

【Steel】21 Steel Mills Halt Production! Construction Steel Shortages and Stockouts; ...

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel】21 Steel Mills Halt Production! Construction Steel Shortages and Stockouts; ... ...

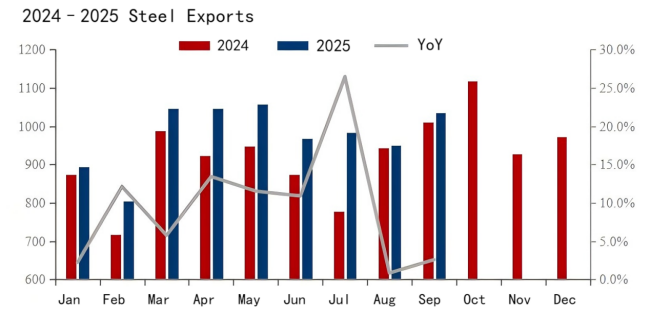

【Steel】Causes and Structural Changes Behind China's High Growth in Steel Exports

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel】Causes and Structural Changes Behind China's High Growth in Steel Export... ...

【Steel Market】October May Experience Fluctuating Trends

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel Market】October May Experience Fluctuating Trends In September 2025, under t... ...

【Steel Miscellaneous Talk】Why Are Developed Countries Exiting Steel Production?

Graphite electrodes are essential in electric arc furnace steelmaking, serving as the core component for arc heating. With excellent conductivity and high-temperature resistance, they play a vital role in ensuring molten steel quality and boosting production efficiency. Controlling graphite electrodes means controlling the key to eaf steelmaking. 【Steel Miscellaneous Talk】Why ... ...

【Steel Prices】After the Frenzy, Nothing but Bubbles – October Steel Price Forecast…

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel Prices】After the Frenzy, Nothing but Bubbles – October Steel Price Forecast… ... ...

【EAF Steel】More Maintenance in EAF Mills, Rebar Inventory Accumulation Slows

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】More Maintenance in EAF Mills, Rebar Inventory Accumulation Slows... ...

【Steel】Analysis of Continuous Profit Contraction and Future Trends

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel】Analysis of Continuous Profit Contraction and Future TrendsSince August, stee... ...

【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills This... ...

【EAF Steel】Demand Remains Weak, Output Edges Down

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】Demand Remains Weak, Output Edges Down This week, China's con... ...

【Steel Market Watch】Are Steel Prices Still Salvageable at Year-End?

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel Market Watch】Are Steel Prices Still Salvageable at Year-End? On December 8, ... ...

【Steel】21 Steel Mills Halt Production! Construction Steel Shortages and Stockouts; ...

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel】21 Steel Mills Halt Production! Construction Steel Shortages and Stockouts; ... ...

【Steel】Causes and Structural Changes Behind China's High Growth in Steel Exports

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel】Causes and Structural Changes Behind China's High Growth in Steel Export... ...

【Steel Market】October May Experience Fluctuating Trends

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel Market】October May Experience Fluctuating Trends In September 2025, under t... ...

【Steel Miscellaneous Talk】Why Are Developed Countries Exiting Steel Production?

Graphite electrodes are essential in electric arc furnace steelmaking, serving as the core component for arc heating. With excellent conductivity and high-temperature resistance, they play a vital role in ensuring molten steel quality and boosting production efficiency. Controlling graphite electrodes means controlling the key to eaf steelmaking. 【Steel Miscellaneous Talk】Why ... ...

【Steel Prices】After the Frenzy, Nothing but Bubbles – October Steel Price Forecast…

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel Prices】After the Frenzy, Nothing but Bubbles – October Steel Price Forecast… ... ...

【EAF Steel】More Maintenance in EAF Mills, Rebar Inventory Accumulation Slows

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】More Maintenance in EAF Mills, Rebar Inventory Accumulation Slows... ...

【Steel】Analysis of Continuous Profit Contraction and Future Trends

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel】Analysis of Continuous Profit Contraction and Future TrendsSince August, stee... ...