Graphite electrodes are essential in EAF steelmaking. They conduct electricity to melt scrap steel with arc heat. Their high conductivity and heat resistance ensure efficient, stable production.

【EAF Steel】9-Week Rally Ends! Losses Deepen + Policy Disruptions, First Output Decline Since CNY

This week, domestic steel prices fluctuated within a narrow range. Transactions in low-price regions were slightly better, but overall downstream user demand remained weak. As of April 17, the average rebar price in China was RMB 3,189/ton, down RMB 13 from the previous week.

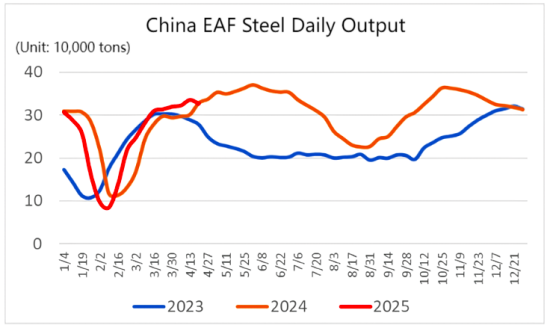

On the raw materials side, domestic scrap steel prices saw a slight rebound this week. Some suppliers were reluctant to sell and held firm on prices. The average purchase price by electric arc furnace (EAF) steel mills increased by RMB 10 from last week to RMB 2,143/ton (excluding tax), further widening the losses and putting pressure on EAF steel production. According to statistics, as of April 17, the capacity utilization rate of 135 EAF steel mills nationwide was 52.22%, down 1.36% from the previous week. Daily EAF steel output dropped to 326,800 tons, ending a 9-week growth streak.

This week, the U.S. government launched a Section 232 investigation into critical mineral imports, escalating tariff tensions. Systemic risks are increasingly impacting the short-term market, and market sentiment remains cautious. In the short term, steel market demand is unlikely to improve significantly. EAF steel mills continue to operate at a loss, which will affect their production enthusiasm. Any potential production increase in the near term will depend on new plate and specialty steel projects coming online in Q2.

China EAF Steel Daily Output

EAF Steel Cost & Profit

Weekly Scrap Supply (China)

0 Replies