【EAF】Long-Term Losses for Steel Mills Lead to Increased Production Cuts and Shutdowns

Graphite electrodes are vital consumables in electric arc furnace (EAF) steelmaking, mainly used for arc heating. With superior electrical conductivity and high-temperature resistance, they are key to improving both the output and quality of EAF steel.

【EAF】Long-Term Losses for Steel Mills Lead to Increased Production Cuts and Shutdowns

As of June 18, a survey of 87 independent electric arc furnace (EAF) steel mills across China showed an average operating rate of 70.93%, down 3.08 percentage points from the previous week, 6.25 percentage points from the previous month, and up 0.53 percentage points year-on-year. Capacity utilization was 54.54%, down 2.19 percentage points week-on-week, 4.96 percentage points month-on-month, and up 0.81 percentage points year-on-year.

This week, both the EAF operating rate and capacity utilization continued to decline. Due to frequent rainfall in many regions, steel sales were poor. Under long-term losses, EAF steel mills further reduced production, and a few mills, under significant pressure, even halted production, leading to a marked drop in operating and utilization rates.

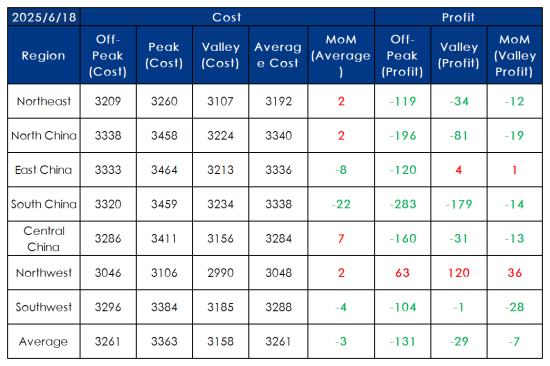

Survey of Independent EAF Construction Steel Mills' Cost and Profit

(As of June 19, 2025; Unit: yuan/ton)

In this survey, 10 out of 76 sample mills were not in production and thus excluded, making the effective number of surveyed mills 66. This week, both cost and profit of EAF steel mills declined.

01.Cost

The average production cost of independent EAF construction steel mills this week was 3,261 yuan/ton, down 3 yuan/ton from last week.

The scrap steel market operated in a consolidated manner, with regional differences. Steel mills adjusted scrap purchasing prices according to their own production conditions, resulting in mixed price changes across regions. Overall, both supply and demand in the market remained weak. Production costs remained largely stable, except in South China, where EAF mills faced higher production costs and engaged in slight price suppression.

Average cost of independent electric arc furnace (unit: yuan/ton)

02. Profit

The average profit for independent EAF construction steel mills this week was -131 yuan/ton, and -29 yuan/ton during off-peak electricity hours, a decline of 7 yuan/ton week-on-week.

Futures prices for rebar were volatile during the week, but persistent rainfall in many regions led to weak steel demand, causing a slight drop in steel prices. The spread between rebar and scrap prices continued to narrow, further squeezing EAF steel mill profits. Except for Northwest China, most other regions saw widespread losses across steel mills, with substantial production pressure.

Profit situation of independent electric arc furnace (unit: yuan/ton)

Summary:

This week, both operating rate and capacity utilization of EAF steel mills continued to decline. Facing long-term losses, steel mills are gradually reducing production or even shutting down. As most EAF mills remain deeply unprofitable, overall production enthusiasm has decreased. Affected by seasonal weak demand, more production cuts and shutdowns are expected. Therefore, EAF operating rates and capacity utilization are likely to continue declining in the near term.

Feel free to contact us anytime for more information about the EAF Steel market. Our team is dedicated to providing you with in-depth insights and customized assistance based on your needs. Whether you have questions about product specifications, market trends, or pricing, we are here to help.

No related results found

0 Replies