Graphite product introduction and common production process

Graphite product introduction and common production process

1. Product introduction

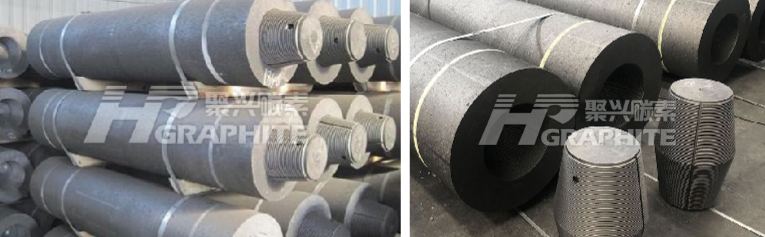

Graphite is an allotrope of elemental carbon, with each carbon atom surrounded by three other carbon atoms arranged in a honeycomb of hexagons. There is a weak van der Waals force between each layer. Since each carbon atom emits one electron, these electrons can move around freely, so graphite is a conductor. The mainstream product graphite electrode, with excellent electrical conductivity and thermal conductivity, is widely used in electric arc furnace and thermal furnace smelting. Graphite is one of the softest minerals, which is opaque and greasy to the touch, varying in color from iron black to steel gray, and its shapes are crystal, sheet, scale, stripe, layered or scattered in metamorphic rocks. Chemical properties are not active, with corrosion resistance.

2. Product application

Graphite is commonly used as a refractory material, mainly used to make graphite crucible in the metallurgical industry, as a protective agent for steel ingots in steelmaking, and as the lining of metallurgical furnaces. It is also used as conductive material: in the electrical industry, it is used to manufacture the electrode, brush, carbon rod, carbon tube, mercury positive current device, graphite gasket, telephone parts, coating of TV picture tube, etc. It can also be used as a wear-resistant lubricating material: graphite is often used as a lubricant in the machinery industry. Because graphite has good chemical stability. A large amount of graphite after special processing is used to make heat exchangers, widely used in petrochemical industry, hydrometallurgy, acid and alkali production, synthetic fiber, paper and other industrial sectors. Can save a lot of metal materials, widely used in atomic energy industry and national defense industry of graphite industry.

3. Common production process

Due to the good floatability of graphite, graphite beneficiation mostly adopts flotation method, and the closed circuit process of multi-stage grinding, multi-stage separation, middle section sequence or centralized reflux is adopted in the flotation process. Under the current technical conditions, the flotation method can only increase its purity (fixed carbon content) to 94-98%. To produce higher purities of high-carbon graphite and high-purity graphite, chemical purification and other methods are required. Main graphite products producing process guidance, welcome to contact us.

No related results found

0 Replies