Types of carburant

Types of carburant

There are many materials that can be used as carburant for cast iron, including artificial graphite, calcined petroleum coke, natural graphite, coke, anthracite and mixtures made from these materials.

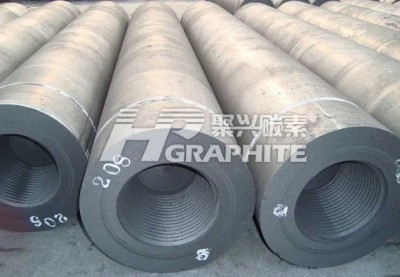

1. Artificial graphite

Among the above-mentioned carburant, the best quality is artificial graphite.

The main raw material for manufacturing artificial graphite is powdered high-quality calcined petroleum coke, with asphalt as binder and a small amount of other auxiliary materials added. After all kinds of raw materials are mixed, they are pressed and then processed in a non-oxidizing atmosphere at 2500~3000 ℃ to graphitize. After high temperature treatment, ash, sulfur and gas contents are greatly reduced.

Due to the high price of artificial graphite products, most of the artificial graphite carburant used in foundries are recycled materials such as chips, waste electrodes and graphite blocks when making graphite electrodes, in order to reduce production costs.

In order to improve the metallurgical quality of nodular cast iron, artificial graphite should be the first choice of carburant.

2. Petroleum coke

Petroleum coke is a widely used carburant at present.

Petroleum coke is a by-product obtained from refining crude oil. The residual oil and petroleum asphalt obtained from crude oil distillation under constant pressure or vacuum distillation can be used as raw materials for manufacturing petroleum coke. After coking, raw petroleum coke can be obtained. The output of raw petroleum coke is less than 5% of the crude oil used. The annual output of raw petroleum coke in the United States is about 30 million tons. The raw petroleum coke has a high content of impurities and cannot be directly used as carburant. It must be calcined first.

Raw petroleum coke includes sponge, needle, granular and fluid forms.

Spongy petroleum coke is produced by delayed coking process. Due to the high content of sulfur and metal, it is usually used as the fuel for calcination, and can also be used as the raw material for calcined petroleum coke. The calcined sponge coke is mainly used in the aluminum industry and as a carburant.

Needle petroleum coke is obtained by delayed coking from raw materials with high aromatic hydrocarbon content and low impurity content. This coke has a needle-like structure that is easy to break, sometimes called graphite coke, which is mainly used to prepare graphite electrodes after calcination.

Granular petroleum coke, which is hard and granular, is obtained by delayed coking from raw materials with high sulfur and asphaltene content and is mainly used as fuel.

Fluid petroleum coke is produced by continuous coking in a fluid bed. It has fine granular shape, non-directional structure, high sulfur content and low volatile content.

The process of calcination of petroleum coke is to remove sulfur, moisture, and volatiles. By calcining the raw petroleum coke at 1200~1350 ℃, it can become basically pure carbon.

The largest application of calcined petroleum coke is in aluminum, about 70% of which is used to make anodes for reducing bauxite. About 6% of the calcined petroleum coke produced in the United States is used as a carburant for iron casting.

3. Natural graphite

Natural graphite can be divided into flake graphite and microcrystalline graphite.

The microcrystalline graphite has high ash content and is generally not used as carburant for iron casting.

There are many kinds of flake graphite: high-carbon flake graphite needs to be extracted by chemical methods, or heated to high temperature to decompose and volatilize the oxide in it. This kind of flake graphite has low output and high price, and generally is not used as carburant; Low carbon flake graphite has high ash content and is not suitable for use as carburant; Medium carbon graphite is mainly used as carburant, but the amount is also small.

4. Coke and anthracite

In the process of electric arc furnace steelmaking, coke or anthracite can be added as carburant during charging. Due to its high content of ash and volatile matter, it is rarely used as carburant in induction furnace melting cast iron. More reports of carburant industry, welcome your contact with us.

No related results found

0 Replies