European steel plants are expected to reduce or stop production in April!

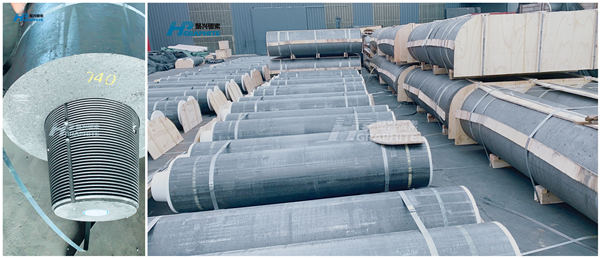

European steel plants are expected to reduce or stop production in AprilIt is reported that due to the recent period of turmoil abroad and the impact of the conflict between Russia and Ukraine, the raw material gap has been ripped. Raw materials prices continue to rise, while steel prices are still slowly catching up, resulting in tight profits. Juxing graphite electrode applie... ...

Domestic graphite electrode prices fell slightly

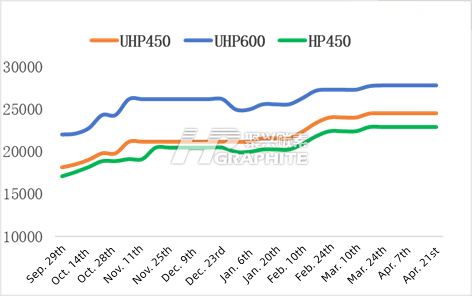

Domestic graphite electrode prices fell slightly This week, domestic graphite electrode prices mainly decreased but individual rise. In most regions, UHP graphite electrode price decreased by 500 yuan/ton, and the price trend of RP and HP graphite electrode was weak. As of press time, UHP graphite electrode φ 450 quoted 24000 yuan/ton, φ 600 quoted 26500-27000 yuan/ton; HP gra... ...

Graphite electrode price is strong and stable, downstream market is traded on demand

Graphite electrode price is strong and stable, downstream market is traded on demandCurrent review: On April 24, domestic graphite electrode market price was strong and stable. At present, downstream steel plants operation continue to be limited, and the demand for graphite electrode has not been released. In terms of cargo arrival, regional differences have widened due to repe... ...

Petroleum coke four consecutive rise within 20 days, 1100 yuan/ton total increase

Petroleum coke four consecutive rise within 20 days, with a total increase of 1100 yuan/ton Since April 20, 2022, petroleum coke price has been increased by 300 yuan/ton, 7800 yuan/ton for train transportation and 7900 yuan/ton for motor transportation; High performance graphite electrode prepared from petroleum coke is produced and supplied by our factory. Calcined coke (mixtu... ...

Raw materials continue to strengthen, electrode stable and rising (4.14-4.21)

Graphite electrode weekly review: Raw materials continue to strengthen, electrode stable and rising (4.14-4.21) This week domestic graphite electrode prices rose slightly. Some small and medium-sized manufacturers in Hunan, Inner Mongolia and Hebei tentatively raise the price by 500-1000 yuan/ton, the leading manufacturer price is temporarily stable, but many manufacturers are... ...

Cost support, graphite electrode prices remain strong and stable

Cost support, graphite electrode prices remain strong and stableCurrent review: On April 19, the domestic graphite electrode market operated strongly and stably. Raw material costs provide strong support for electrode prices. In addition, under the influence of the epidemic, raw materials procurement, enterprise production and spot shipment are under pressure. Spot circulation ... ...

Calcined coke market analysis

Calcined coke market analysis 1. Overview of calcined cokeCalcined petroleum coke is also known as "calcined coke", which is obtained from petroleum coke raw coke calcined at 1000-2000 ℃.Calcined petroleum coke is widely used in steel-making, chemical industry, building materials, casting materials, machinery, petroleum exploration and other industries. (1) Carbon industry can ... ...

Petroleum coke market analysis

Petroleum coke market analysis1. Overview of petroleum cokePetroleum coke is the product of heavy oil obtained from the distillation of crude oil and the separation of light and heavy oil, and then transformed into hot cracking. Petroleum coke can be used in graphite making, smelting, chemical industry and other industries according to its quality. In terms of appearance, coke ... ...

Petroleum coke price-rising, downstream cost price inversion

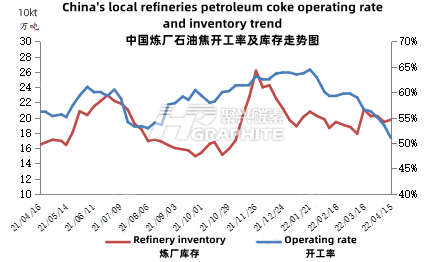

Petroleum coke price-rising, downstream cost price inversion Recently, the petroleum coke market remains strong, and the market price trend is slightly different. The shipment of main refineries is good, and part of coke prices continue to push up; The shipment of local refining enterprises is general, and part of the coke price continues to decline. EAF/LF furnace graphite ele... ...

In the 3RD week of April 2022, national coking units operating rate was 51.02%

In the third week of April 2022, national coking units operating rate was 51.02% As of April 15th, there were 23 existing coking units for routine maintenance, and five new coking units have been suspended for maintenance this week, affecting a total capacity of 6.8 million tons per year, and two sets of coking units in Shandong started coke production, JUXING UHP graphite elec... ...