Cost pressure continues, graphite electrode market bullishness remains

Cost pressure continues, graphite electrode market bullishness remains At present, graphite electrode market is operating strongly. The price of ultra-high power graphite electrode has increased by 1500-3000 yuan/ton. The shipment of raw petroleum coke is good. The prices of Jinxi petroleum coke and Daqing petroleum coke are stable, however market supply is tight and market tra... ...

Domestic ultra-high power graphite electrode prices continue to rise

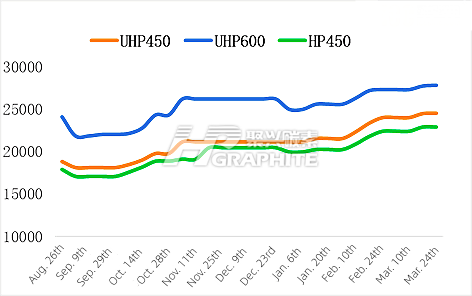

Domestic ultra-high power graphite electrode prices continue to riseThis week, the domestic graphite electrode price was partially adjusted, ultra-high power graphite electrode price increased by 1500 yuan/ton, as of press time, ultra-high power graphite electrode φ450 quoted 24500-25000 yuan/ton and φ600 quoted 275000-28000 yuan/ton; High power graphite electrode φ300-500 quot... ...

Calcined production and marketing transport pressure relief, market prices back up

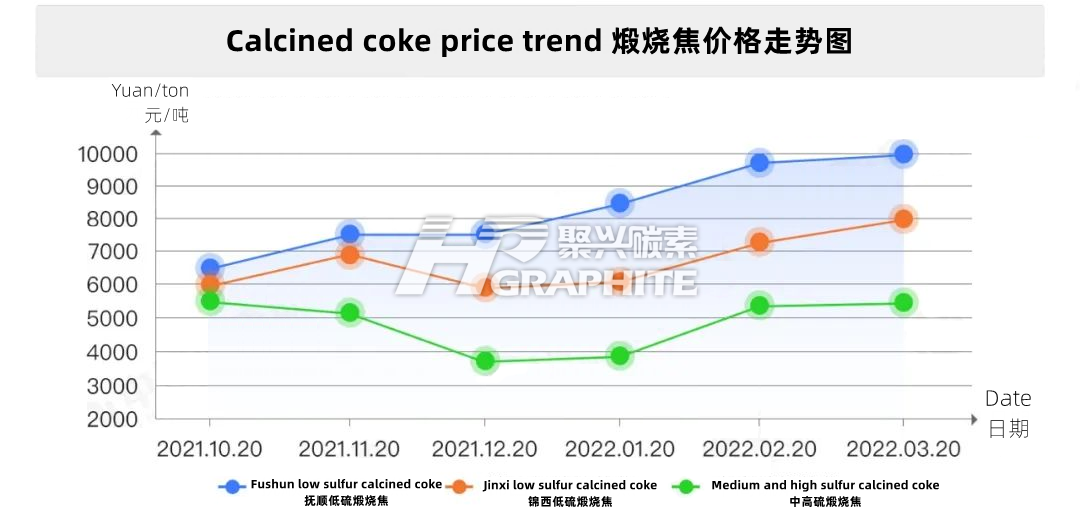

Calcined production and marketing transport pressure relief, market prices back up Latest informationAt present calcined coke market trading turns good, low sulfur calcined coke price has maintained stable operation, and the price of some medium and high sulfur calcined coke has increased. The price of high sulfur calcined coke of Kuqa Dafang increased by 350 yuan/ton to 4800 y... ...

Coal tar pitch supply is tight, the market is pushed up in a narrow range

Coal tar pitch supply is tight, the market is pushed up in a narrow range Upstream market situation: Last week, the domestic coal tar market rose and fell. At this stage, deep processing and carbon black enterprises are still in a loss situation, and the willingness of cutting down price is strong; Juxing graphite powder is mainly uses in the additive for smelting steel or carb... ...

Petroleum coke market shows a bipolar trend, local coking price rises and falls

Petroleum coke market shows a bipolar trend, local coking price rises and falls Last week, petroleum coke market showed a bipolar trend. Mainstream market coke price rose, which up first and then fell. In terms of main business: Sinopec had no pressure on shipment and the inventory was low; PetroChina had high demand in Northwest China and the market trading was good; Juxing gr... ...

Weekly review: Graphite electrode is rising steadily, epidemic affects purchase and shipment

Weekly review: Graphite electrode is rising steadily, epidemic affects purchase and shipment (3.18-3.24) This week the domestic graphite electrode market is rising steadily. After the leading manufacturers focused on raising prices last weekend, a number of small and medium-sized manufacturers also followed up this week, with a range of 500-1000 yuan/ton. At present, UHP450mm s... ...

Graphite electrode market continues to be optimistic, overall price is expected to rise

Graphite electrode market continues to be optimistic, overall price is expected to rise[Graphite electrode] At present, domestic graphite electrode market price is stable, and individual enterprises raise their quotation. Downstream steel plants are positive in picking up goods, but the arrival situation is not optimistic, and basically maintain normal production. At present, ... ...

Calcined coke current price (March 20, 2022)

Calcined coke current price (March 20, 2022)Current reviewUpstream raw materials price decreased and the transportation cost increased.Downstream demand is good and the overall operation is stable. On March 20, 2022, China's calcined coke market operated steadily. The supply of raw material petroleum coke was blocked and the inventory was increased, some prices were reduced... ...

Cost continues to increase, graphite electrode market is firm and strong

Cost continues to increase, graphite electrode market is firm and strong Market dynamicsRecently, China's graphite electrode market price has risen, the high price of raw materials continues to support the cost of graphite electrode. Tight overall supply provides confidence for enterprises to support the price, and the new single price of graphite electrode market has been ... ...

Petroleum coke current price (March 20, 2022)

Petroleum coke current price (March 20, 2022) Current reviewWith epidemic impact, logistics and transportation limitation, the rise of petroleum coke is suspended.Main refinery production is in a stable operation, refined petroleum coke performance is weak.On March 20, 2022, China's petroleum coke market was weak, the coke price of main refineries was stable, while the coke... ...