【Electric Arc Furnace Steel】 Carbon Reduction and Production Control: Benefit or Burden?

【Electric Arc Furnace Steel】 Carbon Reduction and Production Control:

Benefit or Burden?

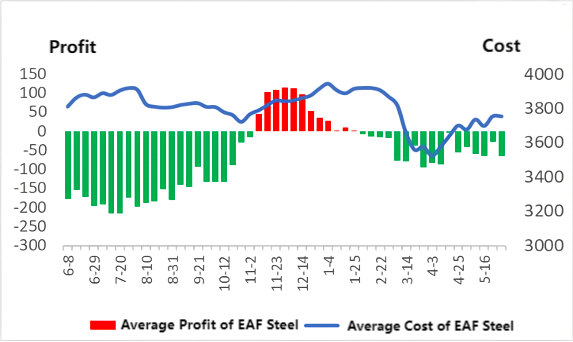

This week, the domestic construction steel market showed a trend of initial decline followed by a rise. In the first half of the week, market transactions were sluggish. However, after the State Council issued the "2024-2025 Energy Conservation and Carbon Reduction Action Plan," market sentiment was temporarily boosted, leading to a price rebound. As of May 30, the average price of rebar in China was 3766 RMB, down 33 RMB from last weekend.

Raw Materials:

This week, scrap steel prices were stable to slightly lower. The average purchase price of scrap steel by electric arc furnace (EAF) steel mills decreased by 7 RMB from last weekend to 2496 RMB (excluding tax). Scrap steel enterprises are not optimistic about the demand for steel in June, showing a marked increase in shipment enthusiasm, with both the arrival volume and inventory of steel mills increasing.

Due to the scrap steel price drop being less than that of steel products, the losses for EAF steel mills expanded again this week, hindering production growth. More enterprises in regions like Guangxi have increased their shutdowns for maintenance. As of May 30, the capacity utilization rate of 135 EAF steel mills nationwide was 60.28%, an increase of 1.29% from the previous week, with EAF steel production reaching 370,800 ton/day. For high-quality graphite electrodes required in EAF steelmaking, refer to the specifications...

Market Outlook:

The current steel market is still characterized by strong expectations but weak reality. The high temperatures and rainy weather in June are likely to affect downstream demand for steel. Furthermore, the favorable policies for real estate and infrastructure are yet to be implemented. For EAF steel mills, the energy conservation and carbon reduction policies and continued control of steel production are not necessarily beneficial. In the past few years, these measures often included across-the-board production cuts for EAF steel mills, without showing support for short-process steelmaking. It is hoped that this year will bring some changes in this regard. Feel free to contact us to learn more about the upstream & downstream of EAF steel market.

No related results found

0 Replies