Carbon production raw materials and uses

Carbon production raw materials and uses

01 Carbon production raw materials

The raw materials for the production of carbon and graphite materials are carbon raw materials. Graphite electrodes for steelmaking are available from stock. Due to different sources and production processes, the chemical structure, morphological characteristics and physical and chemical properties of these compounds are very different. According to the classification of the state of matter, they can be divided into solid raw materials (i.e. aggregates) and liquid raw materials (i.e. binder and impregnant). Among them, solid raw materials can be divided into multi ash raw materials and low ash raw materials according to their inorganic impurity content. Ash content of low ash raw materials is generally less than 1%, such as petroleum coke, asphalt coke, etc. The ash content of multi ash raw materials is generally about 10%, such as metallurgical coke, anthracite, etc. In addition, the returned materials in production, such as graphite scraps can also be used as solid raw materials. Due to the different functions and application scope of various raw materials, they also have different quality requirements. Quartz sand is also used as auxiliary materials in carbon production.

02 Solid raw materials (aggregate)

Aggregate Type | Manufacturing Method | Main Features & Uses |

Petroleum coke | Petroleum is made from heavy oil and light delayed coking. | Low ash content, good graphitization performance and low coefficient of thermal expansion. It is used to manufacture artificial graphite products. |

Asphalt coke | Coal tar pitch is prepared by delayed coking method or furnace chamber method. | Asphalt coke is easier to obtain products with high density and low anisotropy than petroleum coke. Graphitization performance is poor. Used for manufacturing graphite electrode, graphite anode, carbon resistance rod, anode paste, etc. |

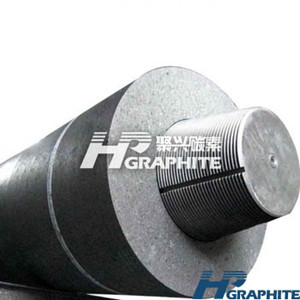

Needle coke | Petroleum heavy oil or coal pitch is prepared by delayed coking after removing impurities and primary QI. | The anisotropy is obvious, the graphitization performance is the best and the coefficient of thermal expansion is small. Used for manufacturing ultra-high power graphite electrode or high power graphite electrode. |

Metallurgical coke | Coal is made by high temperature distillation in a coke oven. | Relatively high mechanical strength, but also high ash content. It is used to produce carbon electrode, carbon block, electrode electrode paste, etc. It is also the filling material of baking furnace and resistance material of graphitization furnace. |

Graphitized metallurgical coke | Metallurgical coke is prepared by graphitization. | Thermal conductivity and conductivity due to metallurgical coke. When producing carbon block and electrode paste, add a little to improve thermal conductivity and conductivity. |

Hard pitch coke | Natural hard asphalt is prepared by coking. | Spherical, high hardness and strength, isotropic. Used for manufacturing density isotropic graphite. |

Anthracite | Natural minerals, mined. | Compact structure, few pores, good wear resistance and corrosion resistance. Used for manufacturing carbon block, electrode paste, seam filling and bonding carbon paste, etc. |

Natural graphite | Natural minerals, mined. | Good oxidation resistance, heat resistance, alkali resistance, excellent conductivity and thermal conductivity, and self-lubricating. Used for manufacturing electric carbon products, mechanical carbon products, impermeable graphite, expanded graphite, etc. |

Carbon ink | Low molecular hydrocarbons are prepared by gas phase carbonization. | As an aggregate additive, it has increased density and hardness, reduced anisotropy, and adjusted resistivity. Used for electric brush, nuclear graphite, etc. |

03 What are the uses of carbon

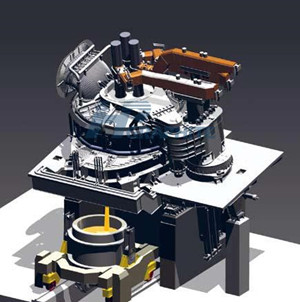

Carbon products are divided into graphite electrode, carbon block, graphite anode, carbon electrode, paste, electric carbon, etc. Commonly known as carbon brick or electric furnace block, mainly used in metallurgical industry: nonferrous metal and colorless metal smelting and calcium carbide, phosphorus chemical enterprises. According to the use of carbon block can be divided into blast furnace carbon block, aluminum carbon block, electric furnace block, etc. Carbon products can be divided into carbon products, graphite products, carbon fiber and graphite fiber according to the processing depth. Carbon products can be divided into graphite products, carbon products, carbon fiber and special graphite products according to different raw materials and production processes. Carbon products can be divided into more ash products and less ash products according to the ash content. The national technical standards and ministerial technical standards of carbon products in China are classified according to different uses and different production processes. This classification method basically reflects the different uses and different production processes of products, and is also convenient for accounting. Therefore, this classification standard is also adopted in its calculation method. In addition, in terms of the quality of carbon products, the carbon products in Ningxia have a great advantage in raw materials because the raw material is Taixi anthracite, and the multi-ash carbon products are among the top in China, reading the related news communicate with us.

No related results found

0 Replies