Graphite Electrode Market Growth, Trends, COVID-19 Impact, and Forecasts (2022 - 2027)

Graphite Electrode Market Growth, Trends, COVID-19 Impact, and Forecasts (2022 - 2027)

The Graphite Electrode Market was valued at USD 8,791. 65 million in 2021 and is projected to register a CAGR of 4. 6%, in terms of revenue, during the forecast period (2022-2027). Due to the COVID-19 pandemic, graphite electrode market was affected negatively in 2020. However, with the resumption of operations in major end-user industries, the market has recovered significantly in 2021.

Main Highlights

In the short term, the strong growth in steel production in emerging countries and the rising availability of steel scrap in China are expected to drive the market’s growth.

On the flip side, soaring prices for needle coke are likely to hinder the growth of the studied market.

The rising production of steel through electric arc furnace (EAF) technology in China is expected to act as an opportunity for the market in the coming years.

The Asia-Pacific region is expected to dominate the market due to strong demand from China.

Market Trends

Electric Arc Furnace Segment to Dominate the Market

Electric arc furnace (EAF) melts steel scrap, DRI (direct reduced iron), HBI (hot briquetted iron, which is compacted DRI), or pig iron in solid form to produce steel. In the EAF route, electricity provides the required power to melt the feedstock.

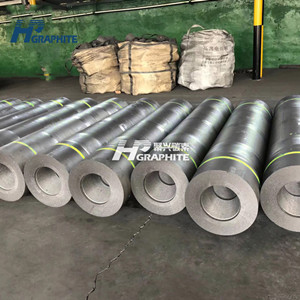

Graphite electrode is primarily used in the electric arc furnace (EAF) steelmaking process to melt steel scrap. Electrodes are made of graphite, owing to their ability to withstand high temperatures. In EAF, the tip of the electrode can reach 3,000º F, which is half the temperature of the surface of the sun. The size of electrodes varies widely from 75 mm to as large as 750 mm in diameter and up to 2,800 mm in length. Electric arc furnaces (EAF) in steel mills and iron and steel foundries commonly use UHP electrodes (usually 350 mm and larger) and HP and UHP electrodes (typically 400 mm and smaller), respectively.

The price surge of graphite electrodes in the recent past has pushed up EAF mills’ costs. The prices of graphite electrodes witnessed a growth of more than 700% in 2019, compared to 2017, in China. Furthermore, As of February 16, 2022, the average price of the graphite electrode in China was 20,818 yuan/ton, up 5.17% from the beginning of the year and 44.48% from the same period last year.

In China, EAF steel accounts for around 10% of the overall share in the current scenario. However, the situation is expected to change due to the growing availability of steel scrap in the country, along with government policies supporting the usage of steel scrap. Due to the factors mentioned above, the demand for graphite electrodes used for EAF applications is expected to increase steadily during the forecast period.

The graphite electrode downstream steel plants are in a recovery state. The graphite electrode stock is insufficient compared with previous years. With the resumption of steel plants, graphite electrode demand is expected to increase.

In conclusion, driven by the favorable demand, tight supply, and high cost in the graphite electrode market, the graphite electrode market price is still expected to rise, which in turn will boost the market demand in the forecast period.

China to Dominate the Asia-Pacific Market

China holds the largest share in terms of consumption and production capacity of graphite electrodes in the global scenario. At present, there are more than 40 official graphite electrode producers in China, with 30 new entrants that make other refractory products, along with electrodes, added to the market in the past 2-3 years.

Chinese manufacturers rushed to install capacity for graphite electrodes from the time the country began to commit heavily to higher rates of steel production via electric arc furnaces in 2017. Furthermore, EAF steelmaking technologies have been strongly encouraged by the decision-making bodies in China in their attempts to reduce carbon emissions and achieve sustainability in the country’s steel industry. The production of vehicles for 2021 accounted for 2,60,82,220 units.

In March 2022, Xinyu Steel started the construction of its 100 metric ton EAF project. The new mill will have a liquid steelmaking capacity of 1 million metric tons/year.

Chinese graphite electrode producers are making constant efforts to procure quality needle coke either via imports or through domestic procurement, along with securing technology for quality improvement. Chinese electrode manufacturers are also focusing on producing more UHP-grade graphite electrodes of sizes larger than 700mm.

The proportion of China's electric furnace steel production is lower than the world average. Driven by policy factors, it is expected that the proportion will continue to increase in the future, which will promote the market demand for ultra-high-power graphite electrodes.

Therefore, the above-mentioned factors are expected to drive the growth of the graphite electrodes market in China. Contact us to learn more about the graphite electrode market.

No related results found

0 Replies