Losses intensified, EAF steel plants reduced or stopped production again and again

Losses intensified, EAF steel plants reduced or stopped production again and again

As of May 18, the average operating rate of the 85 independent EAF (electric arc furnace) steel plants in China was 69.62% through investigation, a decrease of 1.41% compared with last week and 3.12% compared with last month; Capacity utilization rate was 59.29%, down 7.76% compared with last week and 7.34% compared with last month. Juxing graphite electrode has always advocated the use of better materials and more advanced production technology to reduce energy consumption and material cost.This week the capacity utilization rate decreased significantly, mainly because under the sharp dive of rebar futures, spot finished products transaction volume was low and the price fell sharply. Last week, EAF steel plants’ profit has suffered a loss. The loss has not improved, or even increased this week. EAF steel plants has reduced production time or directly stopped production; The operating rate and capacity utilization rate declined. Next week EAF steel profits are difficult to improve in the short term. It is expected that more steel plants will join the ranks of production reduction. Independent EAF operating rate and capacity utilization rate will continue to decline next week.

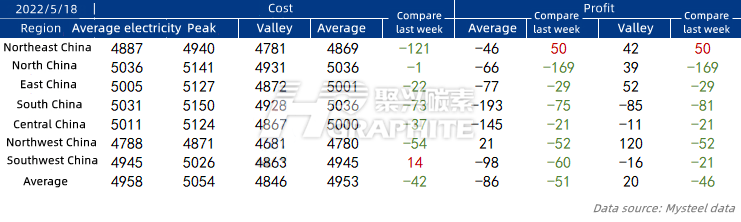

Independent EAF construction steel plants weekly cost investigation (May 18, 2022) (unit: yuan/ton)

According to 40 steel plants sample data this week, of which 5 steel plants have not carried out production, which is not included in this survey. Therefore, 37 independent EAF construction steel plants were investigated this week. The survey showed that the average cost and profit decreased as follows:

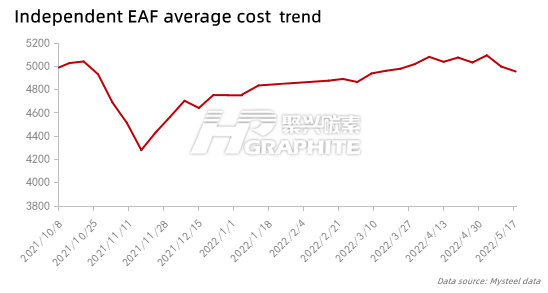

Cost: The average cost of independent electric arc furnace construction steel plant investigated this week was 4953 yuan/ton, down 42 yuan/ton compared with last week. The rebar futures failed to be recovered after heavy drop in last week, which plunged again this week. Under this influence, the scrap purchase prices of steel plants have been continually reduced, and the average cost of independent EAF steel plants has also decreased. It is worth mentioning that most steel plants in South China lowered the scrap purchase price for many times on the May 18th, resulting in a prominent cost decline. The cost of independent EAF in this region decreased by 73 yuan/ton compared with last week; Of course, the largest costs decline of independent EAF is in Northeast China, decrease 121 yuan/ton compared with last week; The cost of Southwest China rose against market trend this week, mainly due to a certain lag of scrap steel adjustment.

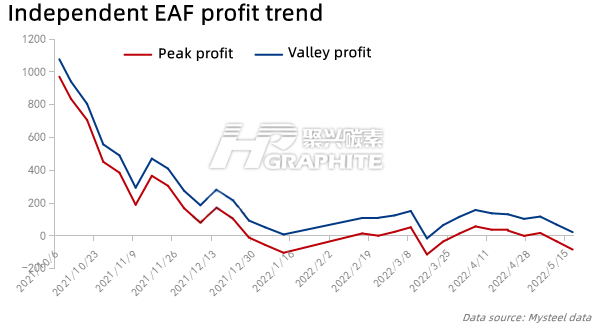

Profit: At present, the average profit of independent EAF steel plant is -86 yuan/ton, down 51 yuan/ton compared with last week, and valley electric profit is 20 yuan/ton, down 46 yuan/ton compared with last week. Under the sharp decline of rebar futures, pessimism was conveyed to the market, and spot price also fell; In most regions, the rebar price fell by more than 130 yuan/ton, the decline range of rebar exceeded that of scrap steel, and the loss of EAF increased. From this week, the loss region of EAF valley power production has expanded, while valley power loss in South China has reached 85 yuan/ton. Under the continuous aggravation of losses, steel plants have reduced production initiatively to eliminate losses.

Overall speaking, at present, steel plants generally suffer losses normally, there is the possibility of further production reduction, scrap steel demand is reduced accordingly, and the price support is weakened. Although the current policy has certain support. On May 15th, the Central Bank issued a interest rate reduction of the first house, but it did not have an immediate effect on rebar futures. It remained at 4600 yuan/ton with shocks after the release. The central government has proposed to strive to achieve economic and social development goals throughout the year and subsequent policy support is expected to be further strengthened, but the recovery may still take time. Under the current situation, the unsaturated production of steel plants will be the norm, and the actions of production reduction and shutdown may occur frequently. It is difficult for scrap market to rise after falling In a short period, the cost of independent EAF plants may be further reduced. More information about EAF steelmaking, please follow us.

No related results found

0 Replies