【Technology Sharing】The structure of the Acheson graphite furnace

【Technology Sharing】The structure of the Acheson graphite furnace

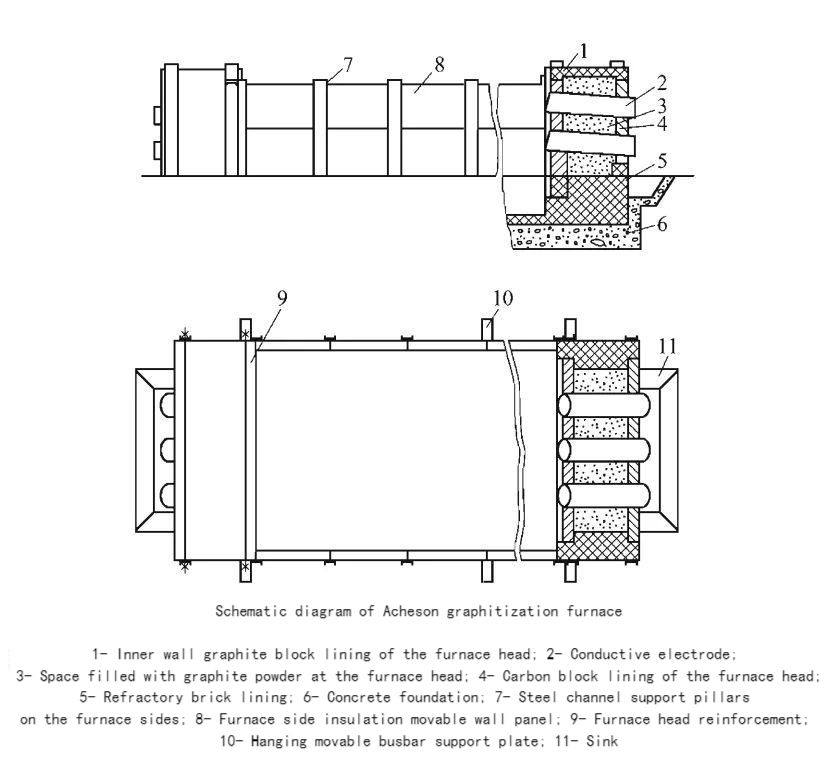

The Acheson graphite furnace (as shown in the figure below) consists of a refractory-lined hearth laid on a reinforced concrete foundation and two end walls with assembled conductive electrode groups, distributed in a rectangular pattern. The function of the end walls is to fix the conductive electrode groups, with refractory bricks or carbon blocks laid on the outer side and graphite blocks on the inner side. The middle part of the wall is filled with graphite powder to form a sealing material space. Several conductive electrodes (graphite electrodes) pass through the end walls, and the diameter and number of electrodes are determined by the current intensity during the operation of the graphite furnace. During the operation, the temperature of the electrodes continuously increases, so cooling is required for the conductive electrodes. Refractory bricks are used to construct side walls on both sides of the furnace, or heat-resistant concrete panels can be vertically placed on both sides of the furnace to replace the side walls. The function of the side walls is to ensure the space occupied by the materials and auxiliary materials.

Small Acheson graphite furnaces have a furnace length of 10 to 12 meters, a furnace width of about 1 meter, and can accommodate about 20 tons of calcined products each time. Medium-sized Acheson graphite furnaces have a furnace length of 14 to 16 meters, a furnace width of about 3 meters, and can accommodate 40 to 50 tons of calcined products each time. Large Acheson graphite furnaces have a furnace length of 18 to 20 meters, a furnace width of about 4 meters, and can accommodate about 100 tons of calcined products each time.

The Acheson graphite furnace is the most widely used graphite furnace in the world. Since its invention in 1895, it has been rapidly promoted in various countries and has dominated the graphite furnace market for a considerable period of time. The Acheson graphite furnace has been continuously improved and perfected since its invention. The development from alternating current furnaces to direct current furnaces represents a significant technological breakthrough. Some key technical indicators (such as power supply time and unit power consumption) and product quality have been greatly improved. However, inherent drawbacks of the Acheson graphite furnace, such as low thermal efficiency, small unit production capacity, and uneven temperature distribution, still exist. The application of series-connected graphite furnaces has ended the dominance of the Acheson graphite furnace. Contact us for the guidance on graphitization technology.

No related results found

0 Replies