Processing of graphite electrode

Processing of graphite electrode

Detailed explanation of graphite electrode process

Raw materials: What are the raw materials used for carbon production?

In carbon production, the commonly used raw materials can be divided into solid carbon raw materials, adhesives and impregnants. HP GRAPHITE provide the high quailty graphite electrodes. Solid carbonaceous raw materials include petroleum coke, asphalt coke, metallurgical coke, anthracite, natural graphite and graphite scrap, etc; Binders and impregnants include coal tar pitch, coal tar, anthracene oil and synthetic resin. In addition, some auxiliary materials are used in production, such as quartz sand, metallurgical coke particles and coke powder. Other special raw materials are used to produce some special carbon and graphite products (such as carbon fiber, activated carbon, pyrolytic carbon, pyrolytic graphite and glass carbon).

Calcination: What is calcination? Which raw materials need to be calcined?

The process of high temperature (1200-1500°C) heat treatment of carbonaceous raw materials in isolation from air is called calcination. Calcination is the first heat treatment process of carbon production. Calcination makes a series of changes in the structure and physicochemical properties of various carbon raw materials.

Anthracite and petroleum coke contain a certain amount of volatile matter and need to be calcined. The coking temperature of asphalt coke and metallurgical coke is relatively high (above 1000°C), equivalent to the temperature of the calcining furnace in the carbon plant, can no longer calcining, only drying water can be. However, if asphalt coke and petroleum coke are mixed before calcination, they should be sent to the calcination furnace together with petroleum coke for calcination. Natural graphite and carbon black need not be calcined.

Compression molding: What is the principle of extrusion molding?

The essence of extrusion process is to make the paste pass through a certain shape of die nozzle under pressure, and then become a wool embryo with a certain shape and size by compaction and plastic deformation. The extrusion process is mainly the plastic deformation process of paste.

The paste extrusion process is carried out in the material chamber (or paste cylinder) and arc nozzle. The hot paste loaded into the chamber is pushed by the rear main plunger. The gas in the paste is forced to be continuously discharged, the paste is continuously dense, and the paste moves forward at the same time. When the paste moves in the cylindrical part of the material chamber, the paste can be regarded as a stable flow, and each granular material layer basically moves in parallel. When the paste enters the extrusion mouth with arc deformation, the paste close to the mouth wall is subjected to large friction resistance, the material layer begins to bend, different propulsion speeds are generated inside the paste, and the inner paste is advanced, resulting in uneven product density along the radial direction. Therefore, the internal stress caused by different internal and external flow velocities is generated in the extrusion block. Finally, the paste enters the linear deformation part and is extruded.

Baking: What is baking? What is the purpose of baking?

Baking is a heat treatment process in which the pressed raw products are heated at a certain heating rate in the protective medium in the heating furnace under the condition of isolating air.

Baking purpose:

(1) Remove volatile matter Products using coal tar pitch as binder generally emit about 10% volatile after baking. Therefore, the baking yield is generally below 90%.

(2) Binder coking The raw products are baked according to certain process conditions to coking the binder, form a coke network between aggregate particles, and firmly connect all aggregates with different particle sizes, so that the products have certain physical and chemical properties. Under the same conditions, the higher the coking rate, the better the quality. Generally, the coking and carbon residue rate of medium temperature asphalt is about 50%.

(3) Fixed geometry During the baking of raw products, softening and binder migration occur. With the increase of temperature, a coking network is formed to stiffen the products. Therefore, the shape does not change with the increase of temperature.

(4) Reduce resistivity In the baking process, due to the elimination of volatiles matter, the coking of asphalt forms coke grid, the decomposition and polymerization of asphalt, and the formation of large hexagonal carbon ring plane network, the resistivity decreases greatly. The resistivity of raw products is about 10000 × 10-6 Ω·m, after baking reduced to 40-50 × 10-6 Ω·m, which is called a good conductor.

(5) Further shrinkage of volume After baking, the diameter of the product shrinks by about 1%, the length shrinks by about 2%, and the volume shrinks by 2-3%.

Impregnation: Why are carbon products impregnated?

The porosity of raw products after press molding is very low. However, after the raw products are baked, part of the coal tar pitch is decomposed into gas and escapes during the baking process, and the other part is coking into asphalt coke. The volume of asphalt coke is much smaller than that of coal tar pitch. Although it shrinks slightly in the baking process, many irregular micro pores with different pore sizes are still formed in the product. For example, the total porosity of graphitized products is generally 25-32%, and that of carbon products is generally 16-25%. The existence of a large number of pores will inevitably have a certain impact on the physical and chemical properties of the product. Generally speaking, the porosity of graphitized products increases, the bulk density decreases, the resistivity increases, the mechanical strength decreases, the oxidation speed increases at a certain temperature, the corrosion resistance also deteriorates, gas and liquid more easily permeable.

Impregnation is a process to reduce the porosity of products, improve the density, increase the compressive strength, reduce the resistivity of finished products and change the physical and chemical properties of products.

Graphitization: What is graphitization? What is the purpose of graphitization?

Graphitization is a high-temperature heat treatment process in which the baked products are heated to high temperature in the protective medium in the graphitization furnace, so that the hexagonal carbon atom plane mesh changes from disordered overlap of two-dimensional space to ordered overlap of three-dimensional space and has graphite structure.

Its purpose is to:

(1) Improve the thermal and electrical conductivity of products.

(2) Improve the heat shock resistance and chemical stability of the product.

(3) Improve the lubricity and wear resistance of products.

(4) Eliminate impurities and improve product strength.

Machining: Why should carbon products be machined?

(1) Need for integrate shapes

With a certain size and shape of pressed carbon raw products, in the process of baking and graphitization of varying degrees of deformation, collision damage, while its surface is also bonded with some filler, if not through mechanical processing can not be used, so the product must be reshaped, processed into the specified geometric shape.

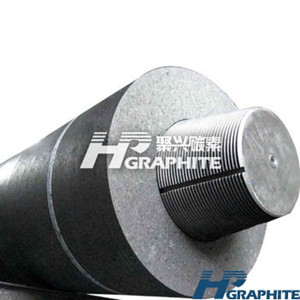

(2) Need for use

Process according to the user's requirements. If the graphite electrode for EAF steelmaking needs to be connected, it must be made into threaded holes at both ends of the product, and then use a special threaded nipple to connect the two electrodes.

(3) Technological needs

Some products should be processed into special shapes and specifications according to the process needs of users, and even require a lower surface roughness, contact us for the pofessional graphite electrode techinical guidance.

No related results found

0 Replies