【Carbon Technology】What Is the Difference Between Natural Graphite and Artificial Graphite?

Artificial graphite electrodes are primarily used in electric arc furnace (EAF) steelmaking, serving as a crucial high-temperature conductive material. They are also widely applied in the aluminum industry, electrolytic cells, and chemical equipment as conductive and heat-resistant components.

【Carbon Technology】What Is the Difference Between Natural Graphite and Artificial Graphite?

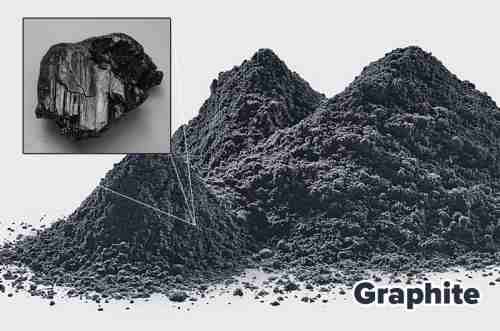

Graphite can be divided into natural graphite and artificial graphite. While they share similar structures and physical-chemical properties, their applications differ significantly.

PART 01: Natural Graphite

Natural graphite forms from carbon-rich organic matter under high-temperature and high-pressure geological conditions over extended periods. Its industrial characteristics are primarily determined by its crystalline form.

Natural graphite is categorized based on its crystalline form into three types: dense crystalline graphite, flake graphite, and cryptocrystalline graphite. In China, the main types are flake graphite and cryptocrystalline graphite.

1. Dense Crystalline Graphite: Also known as lump graphite, it has visible crystals with particle diameters greater than 0.1 mm. The crystals are randomly arranged, forming a dense block structure. It has a high grade, typically with a carbon content of 60%–65%, sometimes reaching 80%–98%. However, its plasticity and lubricity are inferior to flake graphite.

2. Flake Graphite: This type is a single crystal with a flake-like structure, hence the name. It is divided into large and fine flakes. Flake graphite exhibits superior lubricity and plasticity compared to other types, making it highly valuable industrially.

3. Cryptocrystalline Graphite: Also known as amorphous graphite or earthy graphite, and recently referred to as microcrystalline graphite. Its crystal diameter is generally less than 1 micron, visible only under an electron microscope. It can be considered an aggregate of graphite crystals.

Cryptocrystalline graphite typically forms from coal under high-temperature and high-pressure geological conditions and often coexists with coal. It lacks luster, has lower lubricity than flake graphite, and is less selective. However, it has a higher grade, with carbon content generally between 60%–80%, occasionally exceeding 90%.

PART 02: Artificial Graphite

Artificial graphite resembles polycrystalline structures in crystallography. It encompasses various types and production processes. Broadly, any graphite material obtained by carbonizing organic substances followed by high-temperature graphitization is termed artificial graphite, including carbon (graphite) fibers, pyrolytic carbon (graphite), and foam graphite.

Narrowly, artificial graphite refers to block solid materials made from low-impurity carbonaceous raw materials (like petroleum coke, pitch coke) as aggregates and coal tar pitch as a binder, undergoing processes like mixing, kneading, forming, carbonization (baking), and graphitization. Examples include graphite electrodes and isostatic graphite.

PART 03: Differences Between Natural and Artificial Graphite

Given that natural graphite is often used to produce narrow-sense artificial graphite, this section focuses on comparing natural graphite with narrow-sense artificial graphite.

1. Crystal Structure: Natural graphite has well-developed crystals. Flake graphite typically has a graphitization degree above 98%, while cryptocrystalline graphite is usually below 93%. Artificial graphite's crystal development depends on raw materials and heat treatment temperature, generally with a graphitization degree below 90%.

2. Microstructure: Flake graphite is a single crystal with a simple structure, exhibiting anisotropic characteristics. Cryptocrystalline graphite has small, randomly arranged grains with pores after impurity removal, showing isotropic features. Artificial graphite is a multiphase material, including graphite phases from carbonaceous particles and binders, and pores formed during heat treatment.

3. Physical Form: Natural graphite usually exists as powder and is often used in composites. Artificial graphite comes in various forms, including powder, fibers, and blocks. Narrow-sense artificial graphite is typically block-shaped and requires machining into specific shapes for use.

4. Physical and Chemical Properties: Both types are good conductors of heat and electricity. For graphite powders of the same purity and particle size, flake graphite has the best thermal and electrical conductivity, followed by cryptocrystalline graphite, with artificial graphite being the lowest. Flake graphite also has superior lubricity and plasticity.

5. Applications: Graphite's excellent properties make it widely used in metallurgy, machinery, electrical, chemical, textile, and defense industries. Flake graphite's oxidation resistance makes it suitable for refractory materials like magnesia-carbon bricks. Artificial graphite is used for steelmaking electrodes, which natural graphite electrodes can't replace in harsh conditions.

In machinery, graphite materials serve as wear-resistant and lubricating materials. Flake graphite is added to lubricating oils. Equipment transporting corrosive media often uses artificial graphite components like piston rings and bearings, operating without lubricating oil. Natural graphite composites can also be used but have lower wear resistance.

Artificial graphite's corrosion resistance, good thermal conductivity, and low permeability make it ideal for chemical equipment like heat exchangers and reactors. Natural graphite composites are also used but are inferior in thermal conductivity and corrosion resistance.

PART 04: Developing Artificial Graphite from Natural Graphite

Developing new graphite products using artificial graphite production techniques with natural graphite as the main or auxiliary raw material is not new. Many carbon-graphite products have been produced this way, some forming significant industries.

1. Zinc-Manganese Battery Carbon Rods: Made from cryptocrystalline graphite and coal tar pitch, undergoing mixing, extrusion, baking, machining, and waxing. They leverage cryptocrystalline graphite's high conductivity and low cost, with strict impurity content requirements.

2. Natural Graphite Brushes: Produced from flake graphite and coal tar pitch through mixing, rolling, grinding, molding, baking (and graphitization if necessary), and machining. They utilize flake graphite's high conductivity and orientation, requiring low impurity and ash content.

3. Mechanical Carbon-Graphite Materials: Made from natural graphite and coal tar pitch through mixing, rolling, grinding, molding, baking, and precision machining, used in applications requiring high-temperature and corrosion resistance. They demand high purity and low impurity content.

Compared to narrow-sense artificial graphite, these products differ in production processes and performance:

1. They may or may not undergo graphitization above 2500°C. To reduce costs, graphitization is often omitted, resulting in a "carbon" phase from the binder with lower conductivity and higher hardness, affecting performance.

2. Natural graphite's powder form and weak bonding with coal tar pitch lead to higher porosity, lower mechanical strength, and reduced oxidation and thermal shock resistance, limiting product size and application scope.

Technical considerations when developing artificial graphite from natural graphite include:

1. Surface Modification: Natural graphite has fewer oxygen-containing functional groups and lower activity, leading to weak bonding with coal tar pitch. Surface treatment can enhance bonding strength.

2. Purification: Natural graphite's purity is lower than petroleum or pitch coke. High-purity treatment is necessary to improve performance, though it increases costs.

3. Particle Size: Natural graphite's fine particle size limits its use in coarse-structured carbon-graphite products. Techniques like "secondary coking" can address the lack of large particles.

4. Volume Shrinkage: Artificial graphite undergoes significant volume shrinkage during graphitization, increasing density but risking cracks. Natural graphite's lower shrinkage results in lower density and mechanical properties.

Additionally, the cost of high-purity natural graphite approaches or exceeds that of calcined petroleum or pitch coke, making cost control a critical factor.

PART 05: Conclusion

Developing artificial graphite products from natural graphite is a promising way to expand its applications. While natural graphite is already used as an auxiliary material in artificial graphite production, using it as the main raw material presents challenges. Understanding and leveraging natural graphite's structure and properties, and adopting suitable processes, can lead to the production of artificial graphite products with unique structures, properties, and applications.

Note: The figures mentioned are based on data from Steel Union and related sources. For detailed visual representations, please refer to the original charts and graphs.

Feel free to contact us anytime for more information about the Graphite Products market. Our team is dedicated to providing you with in-depth insights and customized assistance based on your needs. Whether you have questions about product specifications, market trends, or pricing, we are here to help.

No related results found

0 Replies