What are the requirements for scrap steel in electric furnace steelmaking?

What are the requirements for scrap steel in electric furnace steelmaking?

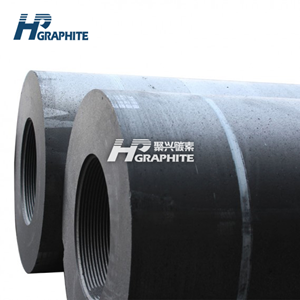

Scrap steel is the basic raw material for EAF (electric arc furnace) steelmaking, accounting for about 70%~90% of steel materials. When molten iron is used in converter steelmaking, due to sufficient heat, up to 30% scrap can be added as coolant to adjust the blowing temperature. Using scrap cooling can reduce the consumption of iron and steel materials, slagging materials and oxygen, and it is more stable and less splashing than using iron ore cooling. Graphite electrode is mainly used in EAF steelmaking process to melt steel scrap.

The quality of scrap steel has a great impact on the technical and economic indicators of steelmaking, and the sources of scrap steel are often very miscellaneous, so the management and processing of scrap steel is very important. Scrap steel should be carefully checked before entering the furnace to strictly prevent the mixing of closed containers, explosives and toxic substances, and pay attention to prevent the mixing of lead, zinc, tin, copper and other non-ferrous metals. In addition, the sludge, refractory materials and slag brought by scrap steel should be minimized.

The scrap of alloy steel should be carefully grouped and kept separately according to the alloy elements contained, so that it can be used to smelt alloy steel by EAF return method to fully recover alloying elements and reduce the cost of steel. Scrap with too large overall dimension and too heavy single piece shall be decomposed and cut in advance, so as to load smoothly without damaging the furnace lining and accelerating melting. The light materials should be packed or pressed block to shorten the loading time.

Light and thin materials that are seriously rusted and stained with oil are not suitable for smelting by return process. In recent years, steel plants using EAFs at home and abroad have developed rapidly. Because the scrap required is mainly purchased from home or abroad, and the purchased scrap is often mixed with various residual alloy elements, which makes it difficult to smelt many kinds of steel. Therefore, sponge iron obtained by the reduction of iron ore at a lower temperature is gradually replacing scrap steel as raw material for EAF steelmaking. Reading more EAF furnace news, please contact us.

No related results found

0 Replies