What kinds of graphite electrode mechanical strength are usually measured?

What kinds of graphite electrode mechanical strength are usually measured?

Industrial production mainly measures compressive strength, flexure strength and tensile strength. Their physical meanings are:

When the external force is pressure, the ultimate resistance of the object during crushing is called compressive strength (or pressure resistance strength).

When the external force is perpendicular to the axis of the object, the ultimate resistance of the object from bending to fracture is called flexure strength (also called bending strength).

When the external force is tensile force, the instantaneous ultimate resistance of the object being pulled is called tensile strength.

The external cause of object damage is also impact force or shear force, but the impact strength or shear strength of carbon products is generally not measured.

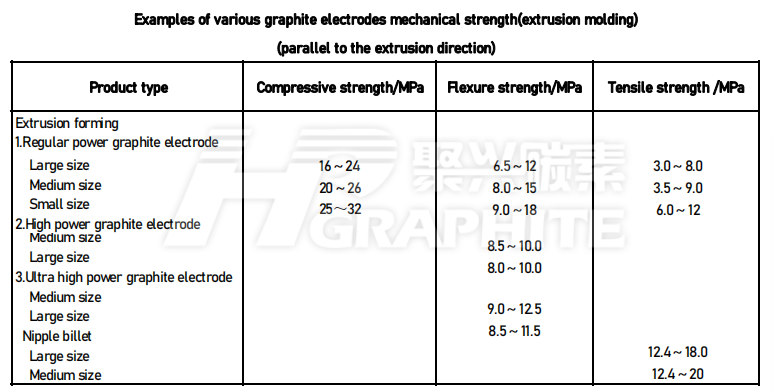

The standard methods for determining the mechanical strength of carbon materials in China are respectively compressive strength (GB 1431-85), flexural strength (GB 3074.1-82) and tensile strength (GB 8721-88). Through many tests, the compressive strength of graphite electrode is about twice of the bending strength (1.61~2.90), and the tensile strength is about half of the bending strength (0.47~0.60). The following table gives examples of three mechanical strength test data for various graphite electrodes.

Generally, the mechanical strength values of carbon and graphite products are anisotropic, that is, the data measured in different stress directions of the same test block have certain differences. For extruded products, the strength of the test block parallel to the extrusion direction is greater than that perpendicular to the extrusion direction; For molded products, the strength along the compression direction is greater than the strength perpendicular to the compression direction.

Various factors affecting the strength of graphite electrode:

1. The greater the particle strength coefficient of raw materials, the greater the mechanical strength of finished products.

2. The ingredients are composed of fine particle size (small particle size and large amount of powder), and the mechanical strength of the final product is high.

3. The mechanical strength of the product produced by using asphalt with higher softening point as the binder is higher than that produced by using asphalt with lower softening point. When batching, the amount of binder should be appropriate. Too much or too little binder will reduce the mechanical strength of the finished product.

4. Insufficient calcination of raw materials will affect the mechanical strength of finished products.

5. If the graphitization temperature of the graphite electrode is too high, the mechanical strength of the finished product will decrease.

6. The mechanical strength of impregnated electrode is higher than that of un-impregnated electrode. With the increase of impregnation times, the mechanical strength increases with the increase of electrode density. For more guidance of graphite electrode industry relevant standards, feel free to contact us.

No related results found

0 Replies