【EAF Steel】Blast Furnace and EAF Cost Inversion, Expected Gradual Improvement in October

【EAF Steel】Blast Furnace and Electric Arc Furnace Cost Inversion, Expected Gradual Improvement in October

This week, the domestic construction steel market in China experienced minor fluctuations, with demand picking up in coastal areas after a typhoon, but transactions remained sluggish in other regions. Traders and end-users exhibited a cautious attitude. As of September 15th, the average price of rebar in China was 3,773 CNY, an increase of 22 CNY compared to the end of the previous week. UHP graphite electrodes are used for electric arc furnace steelmaking, providing excellent electrical and thermal conductivity performance.

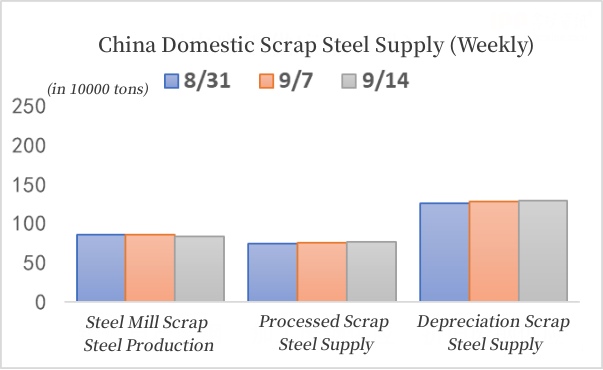

On the raw materials front, supported by pig iron costs, scrap steel prices continued to show relative strength this week. The average purchase price for steel mills' scrap steel (electric furnace material) increased by 6 CNY to 2,565 CNY (without invoices) compared to the previous week, with some bases showing price support. However, the delivery volume to steel mills saw a slight decline compared to the previous month.

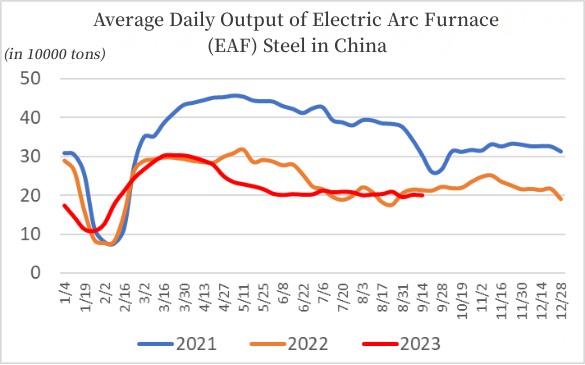

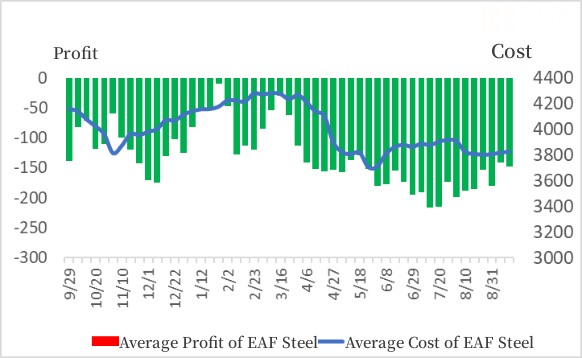

Recently, profits at electric arc furnace (EAF) steel mills have remained relatively stable, with some mills in South China temporarily suspending production due to flooding. According to statistics, as of September 14th, the capacity utilization rate of 135 EAF steel mills across the country was 33.81%, a slight decrease of 0.2% compared to the previous period. The daily production of EAF steel reached 200,100 tons.

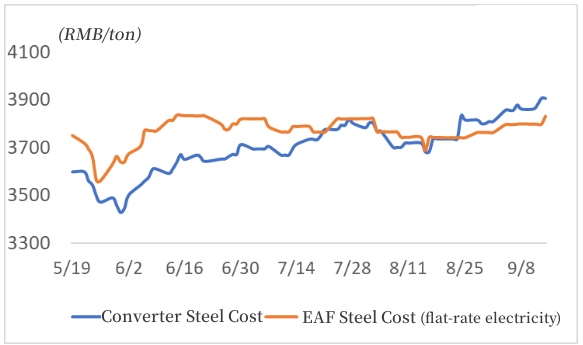

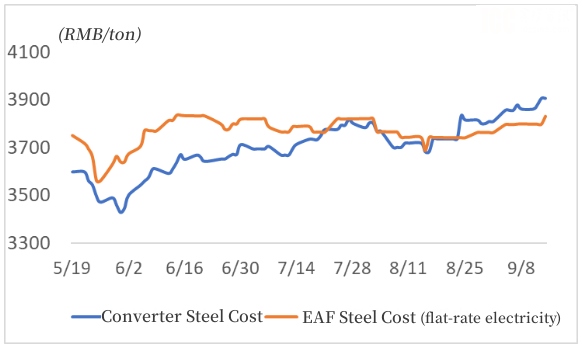

Although the central bank lowered the reserve requirement ratio for bank deposits again this week, the transmission of policy benefits to the steel market still requires time. Steel mills' implementation of production controls is progressing slowly as expected, relying mainly on export growth to alleviate supply and demand pressures. On the other hand, due to the sustained strength of iron ore and coke prices, the profit levels of some small and medium-sized long-process steel mills have gradually approached those of electric furnaces, and in some cases, the cost has exceeded that of electric furnaces. As a result, the probability of proactive production reduction in the fourth quarter is increasing, and the operating environment for EAF steel is expected to gradually improve starting in October. Follow us to learn more about the electric arc furnace (EAF) steel market trends during China National Holiday.

No related results found

0 Replies