Demand change of graphite electrode in new quantum electric arc furnace

Demand change of graphite electrode in new quantum electric arc furnace

Quantum electric furnace is a world advanced electric furnace introduced by Germany Prite company using Siemens and VAI technology. The main equipment includes: automatic scrap loading inclined bridge system, graphite electrode cross arm, fixed furnace cover system, electric furnace body, furnace body opening system, accurate tilting system, FAST siphon slag free tapping system, electric furnace carbon oxygen top gun system, furnace wall burner system, automatic temperature measurement sampling system, furnace bottom blowing argon and temperature monitor system, electrical control system, water cooling control system, hydraulic regulation control system, etc. The electric furnace dedusting adopts the form of dog house to achieve ultra-low emission, and the dust emission concentration is less than 10mg/m3.

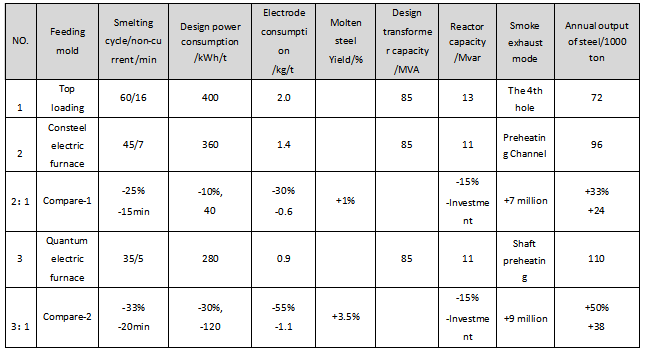

Comparison between quantum electric furnace and ordinary electric furnace

1. Smelting time reduced 20min, shorten 30%, average smelting time ≤40 minutes/furnace, ordinary electric furnace is 60 minutes/furnace. The annual steel output of quantum electric furnace with the same nominal capacity is 50% higher than that of ordinary electric furnace.

2. Compared with ordinary electric furnace, the smelting power consumption of quantum electric furnace decreases by 120kwh/ton steel, down by 30%, lower than 280kwh/ton steel, while ordinary electric furnace is 400kwh/ton steel.

3. Compared with the ordinary electric furnace, the steel material consumption of the same type of scrap quantum electric furnace decreases by 50-60kg/ton steel,reaching 1075kg/ ton steel, the scrap recovery rate increases by 3-4% points, which is 1137kg/ ton steel of ordinary electric furnace, contact us to know more graphite eletrode guidances.

No related results found

0 Replies