【Electric Arc Furnace】Production Pressure Remains, Production Enthusiasm Declines

Graphite electrodes are vital consumables in electric arc furnace (EAF) steelmaking, mainly used for arc heating. With superior electrical conductivity and high-temperature resistance, they are key to improving both the output and quality of EAF steel.

【Electric Arc Furnace】Production Pressure Remains, Production Enthusiasm Declines

As of June 11, a survey of 87 independent electric arc furnace (EAF) steel mills in China shows that the average operating rate was 74.01%, a week-on-week decrease of 2.68%, a month-on-month decrease of 1.19%, and a year-on-year increase of 2.99%. The capacity utilization rate was 56.73%, down 1.97% from last week, up 0.16% from last month, and up 2.34% year-on-year. This week, both the EAF operating rate and capacity utilization rate continued to decline slightly. Due to significant losses among EAF steel mills and long-term financial pressure, some EAF mills have cut back or suspended production, leading to the observed drop in operating and utilization rates.

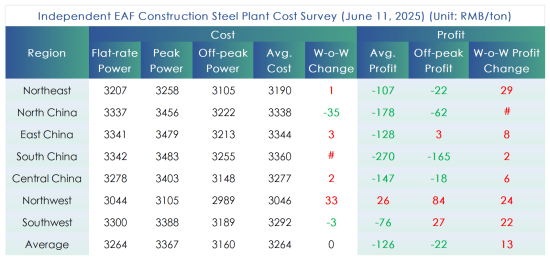

Cost Survey of Independent EAF Construction Steel Mills (June 11, 2025) (Unit: RMB/ton)

Among the 76 sampled steel mills, 8 were not in production and were therefore excluded from the survey. As a result, this week's data includes 68 independent EAF construction steel mills. Compared with last week, the average production cost remained flat, while profits slightly improved. Details are as follows:

Cost

This week, the average production cost of surveyed independent EAF construction steel mills was RMB 3,264/ton, unchanged from last week. The scrap steel market operated steadily with mild fluctuations. Both supply and demand were weak. In some regions, scrap resources were tight, prompting a few steel mills to slightly raise purchase prices. However, mainstream markets remained stable. Overall, steel mills' production costs remained steady.

Profit

This week, the average profit of the surveyed independent EAF construction steel mills was -RMB 126/ton, with off-peak electricity profit at -RMB 22/ton, an increase of RMB 13/ton from last week. During this period, rebar futures rebounded, and spot prices rose slightly. Meanwhile, scrap steel prices were mostly stable, with only a few steel mills raising prices to secure supplies. Thus, the increase in rebar prices outpaced that of scrap, leading to a slight recovery in EAF steel mill profits. However, most EAF mills are still operating at a loss. Coupled with falling prices and the arrival of the hot and rainy season, overall production pressure remains high.

In summary

This week, both the operating rate and capacity utilization rate of EAF mills continued to decline. Due to prolonged losses, some steel mills have begun cutting production or shutting down. Looking ahead, with poor steel demand expected during the hot and rainy season, steel prices may come under further pressure. At the same time, scrap generation from manufacturers and construction sites may decline, potentially supporting scrap prices. The price gap between rebar and scrap may narrow further, increasing the financial strain on EAF steel mills. Therefore, it is expected that EAF operating rates and capacity utilization will continue to decline in the near term.

Feel free to contact us anytime for more information about the EAF Steel market. Our team is dedicated to providing you with in-depth insights and customized assistance based on your needs. Whether you have questions about product specifications, market trends, or pricing, we are here to help.

No related results found

0 Replies