Danieli electric furnace Q-MELT intelligent steelmaking process

Danieli electric furnace Q-MELT intelligent steelmaking process

Q-MELT process technology package

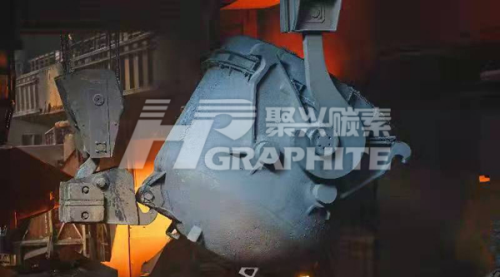

In order to pursue environmental protection and low-carbon process, many factories gradually replace converter steelmaking with EAF (electric arc furnace). In this case, it is critical to ensure the flexibility of the EAF to use a high proportion of molten iron, thus achieving flexibility in the selection of raw materials (scrap and/or molten iron) to minimize the environmental impact. With the proposition of low carbon concept, more and more steel plants use graphite electrode as the conductor of electric arc furnace.

The ability to produce high-quality molten steel at the lowest cost affects the competitiveness of steel manufacturers. The key is to control the diversity of available raw materials and melt them into qualified molten steel in the most effective way.

The adaptive process control technology provided by Danieli Q-MELT process technology package can meet these requirements. Q-MELT can quickly modify EAF parameters, while maintaining the stable operation, shorten the stable conversion time between different raw material ratios as much as possible and achieve the best production cost.

Major function

Q-MELT can identify any trend deviating from the expected process by analyzing various signals sent by industry 4.0 standard sensors, and adjust EAF parameters according to the best practices:

lQ-REG electrode control regulator

lLINDARC real-time gas analyzer based on laser realizes closed-loop control of soft oxygen blowing during scrap smelting

lMeltmodel can dynamically adjust the set value of oxygen flow in the refining process according to the oxidation level of the molten pool

The core of automation system is the smelting pattern. The Fingerprint™ Fingerprint system automatically identifies deviations in process control variables and then corrects them to avoid lost or wasted energy.

The real-time online flue gas analysis is carried out through the on-site laser system, which promotes the process tracking and can be further optimized through feasible closed-loop control of fuel and secondary combustion.

Based on the statistical analysis of all available data (smelting curve, consumption, flue gas analysis and residual error, etc.), a new method is used to evaluate the expected process performance of management.

Conclusion

In view of the fact that many EAFs are now integrated into integrated plants, each day they face challenges of competitive costs and economic sustainability. Through Q-MELT, these plants will be able to dynamically adapt to different market environments, improve the repeatability of process and metallurgical requirements, adhere to implementing best operating practices in the shortest possible time, and support operators and management in the best way, so as to minimize risks.

Since many electric arc furnaces are now integrated into integrated plants, they face challenges of competitive cost and economic sustainability every day. Through Q-MELT, these plants will be able to dynamically adapt to different market environments, improve the repeatability of process and metallurgical requirements, adhere to implementing best practices in the shortest possible time, and support operators and management in the best way, so as to minimize risks. As the graphite industry senior development team, we are ready to provide you with professional services.

No related results found

0 Replies