What are the causes of graphite electrode fracture?

What are the causes of graphite electrode fracture?

How to avoid graphite electrode breaking and tripping during steelmaking?

The following describes the effective measures to avoid graphite electrode breaking and tripping during steelmaking:

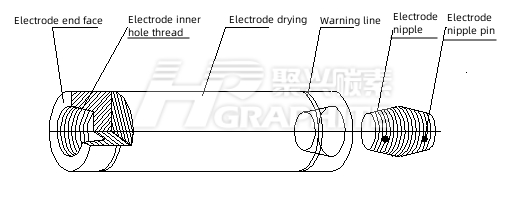

1. The torque applied during graphite electrodes connection shall be appropriate.

2. Scrap should be evenly distributed in the steel furnace, and large pieces of scrap should be placed at the bottom of the furnace as far as possible.

3. Avoid using non-conductive materials in scrap steel.

4. Before and during the connection of graphite electrode, prevent the electrode hole thread and nipple thread from mechanical damage.

5. Avoid clamping the electrode holder at the electrode nipple and the electrode nipple hole.

6. Select electrode nipples with high strength and high machining accuracy.

7. Electrode hole and nipple shall be protected from steel slag or foreign matter embedding which may affect the connection.

8. The phase sequence of graphite electrodes shall be correct, counterclockwise.

9. Electrode columns should be aligned with the furnace top hole and kept parallel. Furnace top hole wall should be cleaned regularly to avoid residual steel slag accumulation and graphite electrode fracture.

10. Keep the electric furnace tilting system in good condition and keep the electric furnace tilting balance.

For instructions on the installation and use of graphite electrode, contact us for details.

No related results found

0 Replies