What are the packaging and transportation methods of graphite electrode?

What are the packaging and transportation methods of graphite electrode?

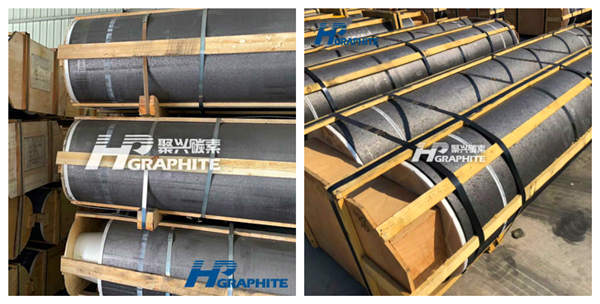

Ⅰ. Packaging of graphite electrode:

1. Connection method: Connect one end of electrode to the nipple, and then pack and deliver the product. The main function of packaging is to protect electrodes from damage during storage and transportation, especially the threaded part.

2. Separately packed electrodes and nipples should be individually packaged and shipped.

Ⅱ. Transportation and storage of graphite electrode:

1. Electrodes must be protected from rain and moisture. Wet electrode should be dried before use to avoid cracks and increased oxidation in the process of steelmaking.

2. When loading and unloading nipple box, handle it with care to avoid nipples collision and thread damage.

3. When lifting or inverting electrode, pay attention to prevent electrode from falling down and damaging electrode.

4. To ensure that electrode end face and thread are in good condition, do not hook electrode directly at both ends of the hole to lift electrode.

5. Do not stack electrodes and nipples directly on the ground, instead, place them on wooden or iron racks to prevent them from being damaged or sticking to the soil. Do not unpack the temporarily unused electrodes and nipples to prevent dust and debris from falling on the threads or in the electrode holes.

Ⅲ. Graphite processing classification:

1. Ultra-high power graphite electrode

Graphite electrodes with current density greater than 25A/cm2 are allowed, mainly used in ultra high power steel arc furnace for steelmaking.

2. High-power graphite electrode

Graphite electrodes with current density of 18~25A/cm2 are allowed, mainly used in high-power arc furnaces for steelmaking.

3. Oxidation resistant graphite electrode

Graphite electrode with anti-oxidation protective layer (graphite electrode antioxygen) on the surface. Forming conductive and high temperature oxidation resistant protective layer, reducing the electrode consumption (19%~50%) during the graphite electrode steelmaking, extending the electrode service life (22%~60%), and reducing the electric energy consumption of the electrode.

4. Regular power graphite electrode

Graphite electrodes with current density lower than 17A/cm2 are allowed, mainly used in regular electric furnaces for steelmaking, silicon smelting, yellow phosphorus smelting, etc. Graphite electrode packaging and transportation professional guidance, contact us to learn more.

No related results found

0 Replies