【Carbon Knowledge】Purpose and Methods of Graphitization

【Carbon Knowledge】Purpose and Methods of Graphitization

1. Purpose and Methods of Graphitization

The production process of carbon & graphite materials and products is characterized by multiple stages, with the most complex and crucial stage being graphitization. Graphitization involves placing the calcined product in a high-temperature furnace, heating it to above 2300 to 2500°C in a protective atmosphere. This process transforms the hexagonal carbon atom plane lattice from disordered two-dimensional space (amorphous carbon) into an ordered three-dimensional space, forming a graphite structure. Go check the specifications of the widely used product: graphitized petroleum coke.

The purposes and effects of graphitization are as follows:

(1)Enhance the material's thermal conductivity and electrical conductivity.

(2)Improve the material's thermal stability, resistance to thermal shocks, and chemical stability.

(3)Enhance the material's lubrication performance and wear resistance.

(4)Remove impurities from the material and increase purity.

(5)Reduce the material's hardness for ease of mechanical processing.

2. Methods of Graphitization

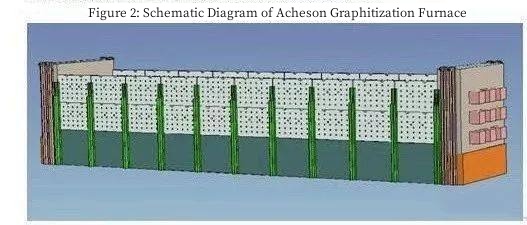

Since the invention of the graphitization furnace (known as the Acheson furnace) by E.G. Acheson in 1895, artificial graphite production has a history of over a century. During this period, although the principles of Acheson's furnace have remained the foundation of artificial graphite production, there have been numerous improvements and developments in graphitization equipment and structures. These include alternating current (AC) and direct current (DC) Acheson furnaces, as well as other methods such as internal thermal series furnaces, box furnaces, PC furnaces, and continuous graphitization furnaces.

Graphitization methods can be categorized as follows:

1) By Heating Method: This categorization includes direct and indirect methods. In the direct method, the power source is in direct contact with the product, which itself is conductive. The product is heated through resistive heating to reach the graphitization temperature. This method includes Acheson's method with resistive materials and Castner's method (or internal thermal series graphitization) without resistive materials. The indirect method involves the power source not being in direct contact with the product, and heat is transferred through induction or radiation. Generally, the product can move within the furnace, as seen in continuous graphitization furnaces.

2) By Operation Mode: It can be categorized into batch and continuous methods. Acheson furnaces and series furnaces are examples of batch graphitization.

3) By Current Type: Graphitization can be classified into alternating current (AC) and direct current (DC) graphitization. Currently, direct current graphitization is commonly used.

In the production of artificial graphite, Acheson furnaces are frequently employed. For large and extra-large products, internal thermal series graphitization furnaces have gained popularity in China. Continuous graphitization furnaces are suitable for small products like electrode carbons. For small carbon rods such as arc carbon rods, simply connecting the power source to the two ends of the carbon rod and passing current for a few seconds or a dozen seconds can achieve graphitization. The PC furnace operates on a principle similar to that of the Castner furnace and was developed and used by the former Soviet Union. Contact us to learn more about the core knowledge of the carbon industry.

No related results found

0 Replies