【Calcined Petroleum Coke】Effect of Volatile Matter Content on Anode Production

【Calcined Petroleum Coke】Effect of Volatile Matter Content on Anode Production

One of the key indicators for evaluating the performance of calcined petroleum coke is its volatile matter content.

If the volatile matter of calcined petroleum coke is too high, the shrinkage ratio of green anodes during baking will increase, and in severe cases may even lead to anode cracking. At present, the quality of petroleum coke is becoming increasingly unstable, especially with large fluctuations in volatile matter and sulfur content. In order to produce cost-effective anode products, carbon enterprises must control and blend petroleum coke with respect to both volatile matter and sulfur content.

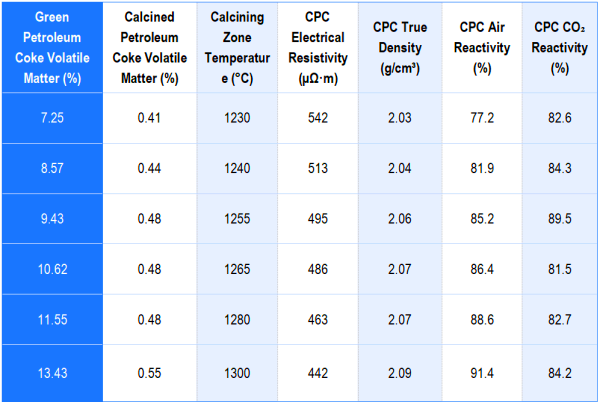

In this study, petroleum coke with volatile matter ranging from 7% to 13% was calcined and blended. The calcination was carried out in the calcining furnace of a certain enterprise. After testing and analyzing the calcined petroleum coke, the corresponding performance indicators were obtained.

Effect of Different Volatile Matter Levels of Petroleum Coke on the Quality Indicators of calcined petroleum coke

From the above data, it can be seen that as the volatile matter content of petroleum coke increases from low to high, the calcining zone temperature gradually rises, and the volatile matter, true density, air reactivity, and CO₂ reactivity of the calcined petroleum coke also all show increasing trends.

Analysis of the above data indicates that when the volatile matter content of petroleum coke is low, the calcining zone temperature will not be too high; however, the raw material cannot be fully calcined and cannot meet the required calcining process parameters. The petroleum coke cannot undergo sufficient physical and chemical reactions, resulting in low true density and small volume shrinkage, making the calcination process ineffective.

On the contrary, when the volatile matter content of petroleum coke is too high, it will first cause the overall furnace temperature to be excessively high, damaging the furnace body and reducing its service life; secondly, it will lead to coke deposition inside the pots, blocking volatile gas passages, reducing discharge rate, and affecting product quality.

At the same time, the data also show that for petroleum coke with lower volatile matter, the quality of the resulting calcined petroleum coke is unstable. Under the same calcining conditions, the true density of the calcined petroleum coke obtained is 0.02 g/cm³ lower than that of calcined petroleum coke produced from petroleum coke with normal volatile matter, and other performance indicators are also inferior. Therefore, simply using petroleum coke with low volatile matter as the sole raw material cannot meet the requirements for producing high-quality anode products.

The use of pot-type calcining furnaces has advantages such as higher calcined petroleum coke bulk density, higher calcining temperature, lower carbon loss, and lower energy consumption. Pot-type calcining furnaces rely entirely on the volatile matter released from petroleum coke to burn in the flue channels for heating, and only a vertical wall separates the flue from the material, enabling full utilization of the thermal energy of the raw material, which is in line with energy-saving development directions.

However, when the volatile matter content of the raw material is too low, the material cannot be fully calcined, resulting in poor calcined petroleum coke quality, making it unsuitable for producing high-quality anode products. When the volatile matter content is too high, it can easily raise the overall furnace temperature, and petroleum coke with lower volatile matter must be blended in a certain proportion to prevent coke deposition inside the furnace during calcination. Therefore, obtaining petroleum coke raw materials with appropriate volatile matter through blending technology is of great significance for improving product quality and extending the service life of the calcining furnace.

Feel free to contact us anytime for more information about the calcined petroleum coke market. Our team is dedicated to providing you with in-depth insights and customized assistance based on your needs. Whether you have questions about product specifications, market trends, or pricing, we are here to help.

No related results found

0 Replies