Steel industry is expected to perform poorly, EAF production is still under pressure

Mysteel interpretation: Steel industry is expected to perform poorly, EAF production in the short term is still under pressure

As of October 26, 85 independent EAF steel plants in China have been investigated, the average operating rate was 60.46%, which increased 2.51% week-on-week and decreased 0.71% month-on-month; The capacity utilization rate was 52.47%, with a increase of 3.02% week-on-week and a decrease of 0.62% month-on-month. EAF steelmaking is to use the graphite electrode to introduce current into the furnace, and use the high temperature heat source generated by the electric arc between the electrode end and the furnace charge to smelt. This week, both production resumption and production reduction appear in EAF steel plants. Some EAF steel plants in Eastern and Southern China resumed production and increased output. At the same time, however, some steel plants in Central and Eastern China have stopped production or reduced production, and the enterprises began to adjust production according to their own profitability. The production capacity of the reproducing steel plant is large, which leads to the operation rate and capacity utilization rate of the EAF steel plant rise obviously.

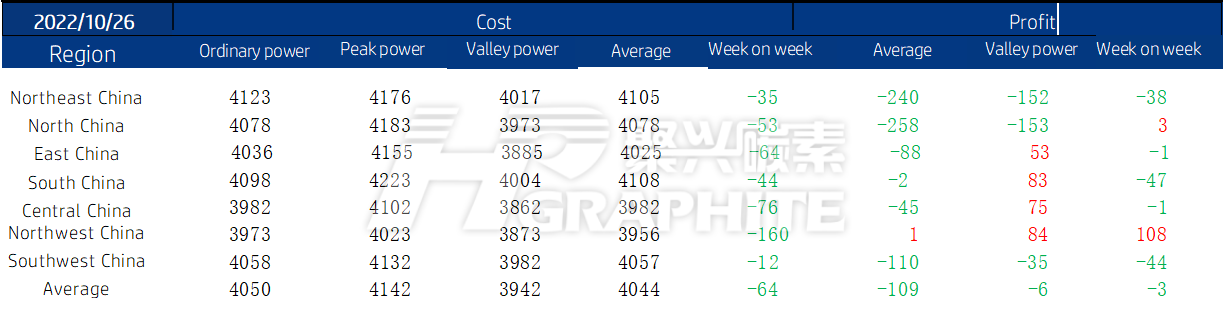

Weekly Cost Investigation of Independent EAF Construction Steel Plants (October 8, 2022) (Unit: yuan/ton)

8 steel plants were not producing in the 40 sample data, which was not included in the survey. Therefore, the number of independent EAF construction steel plants in the survey was 32. The survey showed that steel plants' production costs and profits fell. The situation was as follows:

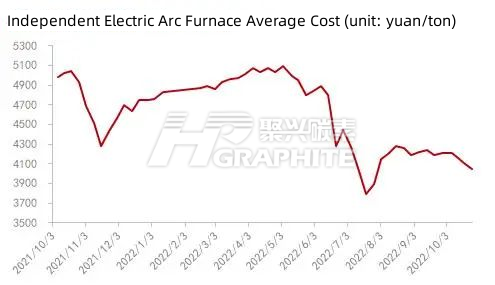

Cost: The average cost of the independent EAF construction steel plant surveyed this week was 4044 yuan/ton, with a weekly reduction of 64 yuan/ton. This week, due to the weak demand in the steel market, the price fell sharply, leading to steel plants to significantly reduce the purchase price of scrap steel. Scrap steel prices fell to between 30 and 150 yuan/ton. Costs have fallen even less in the Southwest. While scrap prices have fallen by 40-60 yuan/ton, electricity bills for steel plants in Southwest China have risen, driving up costs. The biggest drop was in the Northwest, mainly due to the impact of the upcoming overhaul of local steel plants. Scrap prices have fallen sharply, resulting in a significant drop in costs.

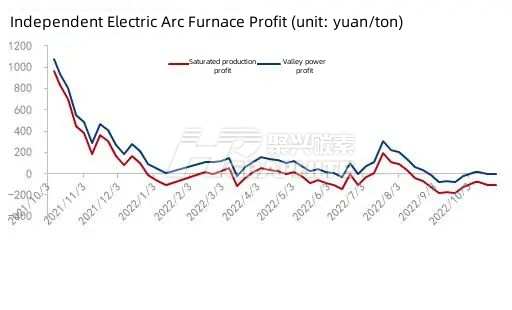

Profit: The average profit was -109 yuan/ton, valley power was -6 yuan/ton, with a decrease of 3 yuan/ton week-on-week. This week, the demand for steel decreased, especially in the North, and rebar prices fell significantly, and the decline was greater than that of scrap steel, resulting in the continuous compression of the profits of steel plants. From the perspective of profits, the saturated production of steel plants was still in a loss state, and valley power performance was differentiated. From the perspective of regions, the losses of steel plants in the North were relatively serious, the losses of valley power in the Southwest were small, and valley power profits in other regions were marginal. At present, steel plants production pressure is large, net profit may still be in the loss state.

On the whole, the current EAF steel plant is still basically in a loss state. In November, the demand for steel in the north will be sluggish, and the steel price may decline significantly. The EAF steel plant will still produce under pressure. In terms of scrap, the current drop in scrap prices is basically consistent with the decline in rebar prices. The production cost of steel plants has not decreased significantly, and the EAF steel plants will still be in a loss state for a short time. Reading the reports of EAF steel future performance, welcome to contact us.

No related results found

0 Replies