【EAF Steel】Survey Statistics on Independent EAF Production in China Before the New Year

【EAF Steel】Survey Statistics on Independent EAF Production in China Before the New Year

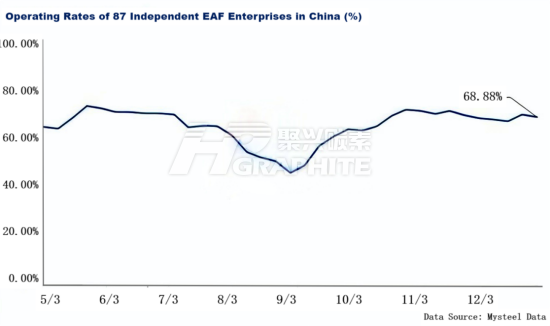

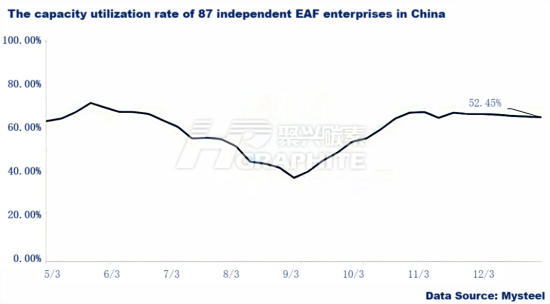

As of late December 2024, a survey of 87 independent electric arc furnace (EAF) steel mills in China (including 76 mills producing construction steel) revealed the following:

Operating Rate: The average operating rate was 68.88%, a decrease of 1.01 percentage points month-on-month and 4.76 percentage points year-on-year.The Northwest region saw a slight increase, the East region experienced a slight decrease, the Southwest and Central regions declined significantly, and other regions remained stable. The scale of electric arc furnaces continues to expand, and power consumption continues to increase. Graphite electrodes contribute to the stable operation of electric arc furnaces.

Capacity Utilization: The average capacity utilization rate was 52.45%, down 0.34 percentage points month-on-month and 12.94 percentage points year-on-year. The Northwest region experienced a slight increase, the Southwest and South regions saw slight decreases, the Central region declined significantly, and other regions remained stable.

Daily Crude Steel Output: Among the 87 independent EAF steel mills, daily crude steel output decreased by 0.47% month-on-month.

Weekly Production of Construction Steel: For the 76 construction steel EAF mills, weekly rebar production decreased by 2.06%, while wire rod production increased by 2.02%.

Profitability: Among the 76 construction steel EAF mills, 34.21% reported slight profits, 53.95% broke even (some due to production halts), and 11.84% incurred losses.

This week, operating rates and capacity utilization at independent EAF steel mills slightly declined. In the Central region, a steel mill in Henan temporarily halted production due to environmental concerns, affecting approximately 0.12 million tons of daily output. In the East, a steel mill in Jiangxi completed maintenance this week, resuming operations. In the Northwest, a steel mill in Shaanxi resumed production with one EAF, while another remains idle due to environmental reasons.

Overall profitability among independent EAF steel mills remained stable, attributed to regional shortages and price recoveries. Towards year-end, several regions issued air pollution alerts, prompting temporary production halts. In the Southwest, mills continued to reduce output due to scrap shortages.

As the Spring Festival approaches, many mills are planning holiday shutdowns, primarily around mid-January. It's anticipated that operating rates and capacity utilization at independent EAF mills will continue to decline in the coming week.

Feel free to contact us anytime for more information about the EAF steel market. Our team is dedicated to providing you with in-depth insights and customized assistance based on your needs. Whether you have questions about product specifications, market trends, or pricing, we are here to help.

No related results found

0 Replies