【EAF Steelmaking】Benefiting from Blast Furnace Cutbacks, EAF Steel Production Sees a Modest Recovery

【EAF Steelmaking】Benefiting from Blast Furnace Cutbacks,

Electric Arc Furnace Steel Production Sees a Modest Recovery

After the National Day holiday, China domestic construction steel market has seen lackluster transactions. Both end-users and traders are cautious about stocking up, exacerbated by the impact of excess inventories during the National Day holiday, resulting in an overall slight price decline in the market. As of October 13, the average price of domestic rebar is 3,722 yuan, down 29 yuan compared to the previous weekend.

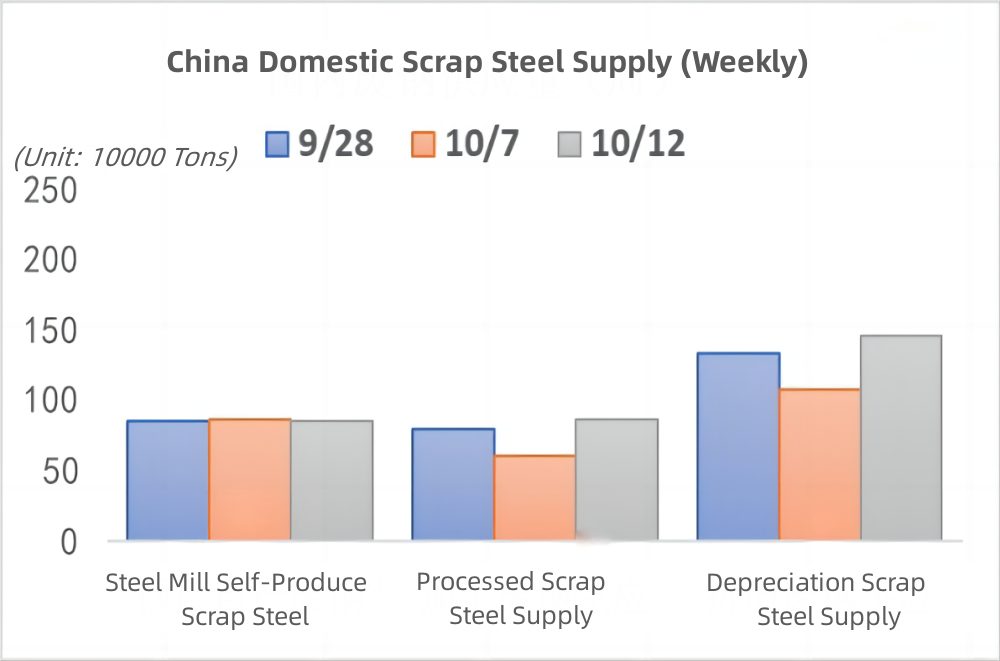

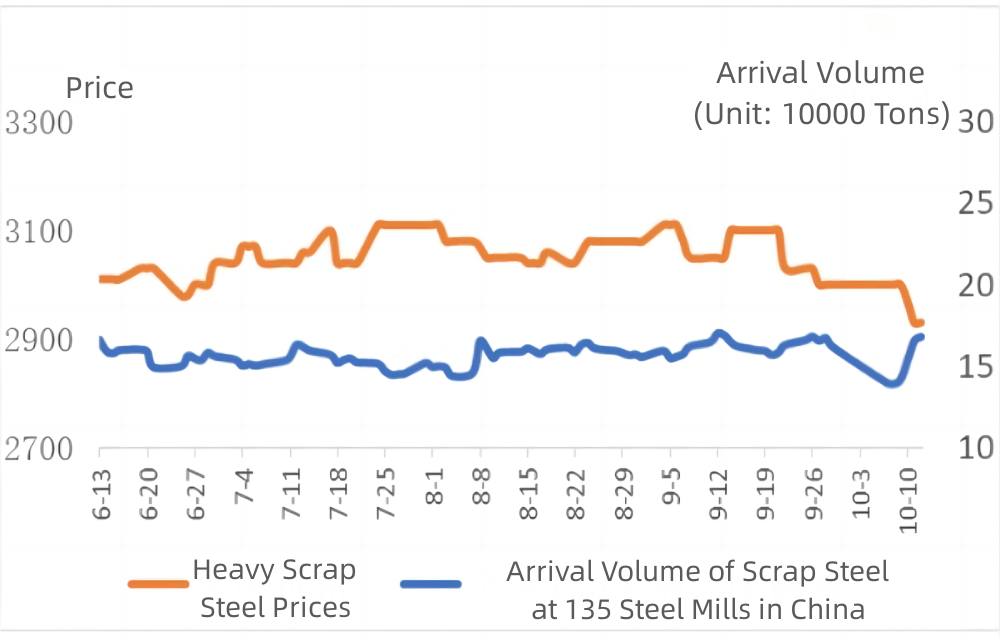

On the raw material side, during the National Day holiday, market resources became tighter, with some steel mills raising their procurement prices by 30-40 yuan. However, after the holiday, as steel prices weakened, many steel mills slightly reduced their scrap steel procurement prices. Some production bases became pessimistic about the future and significantly increased their shipping efforts. The arrival and inventory of scrap steel at steel mills both increased slightly.

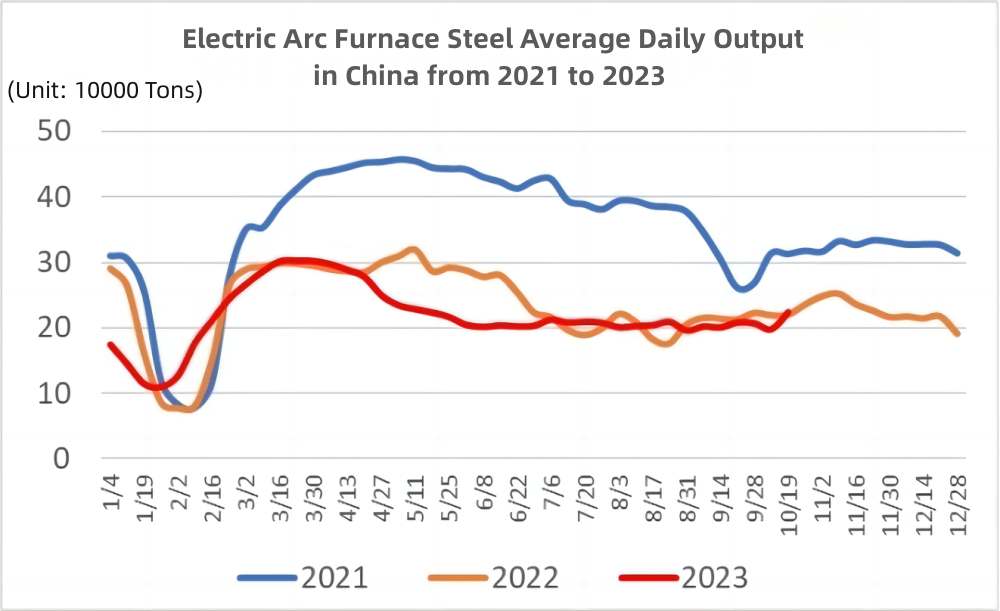

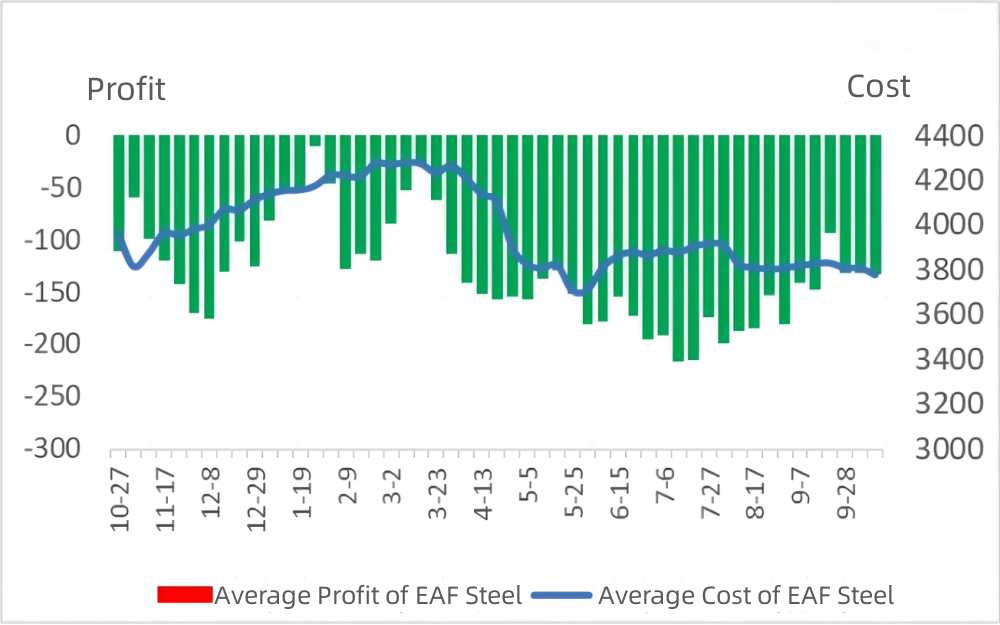

The price decline of scrap steel this week is roughly on par with that of rebar. Electric furnace steel mills did not experience significant changes in profitability, and their overall mindset is becoming more stable. Many electric furnaces in East China and Southwest China resumed production after the holiday, leading to increased electric furnace steel production. To continue learning about the latest market of graphite electrode products. According to statistics, as of October 12, the capacity utilization rate of 135 electric furnace steel mills nationwide was 37.79%, an increase of 4.46% compared to the previous period, and electric furnace steel production reached 223,700 tons per day.

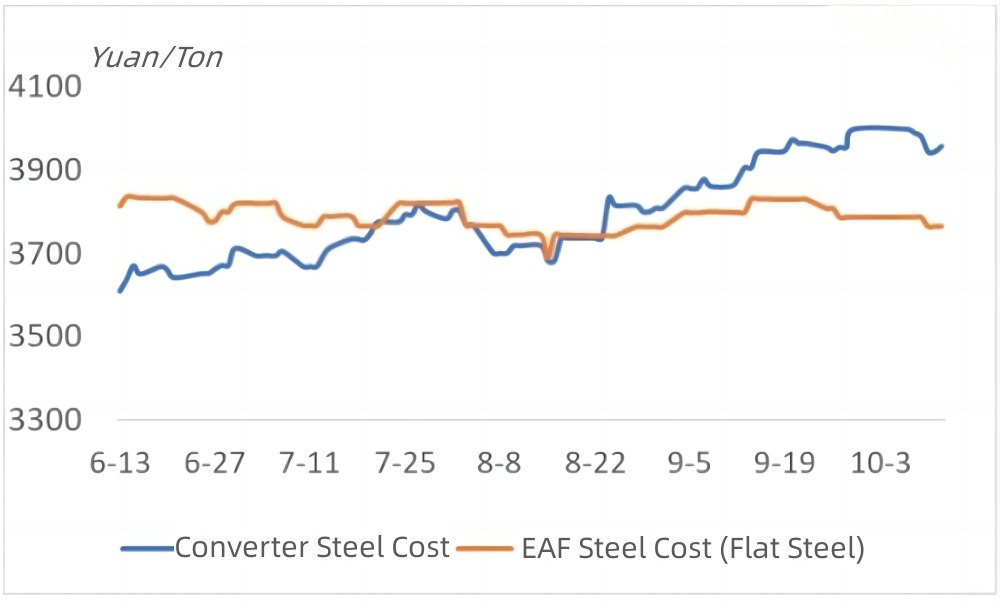

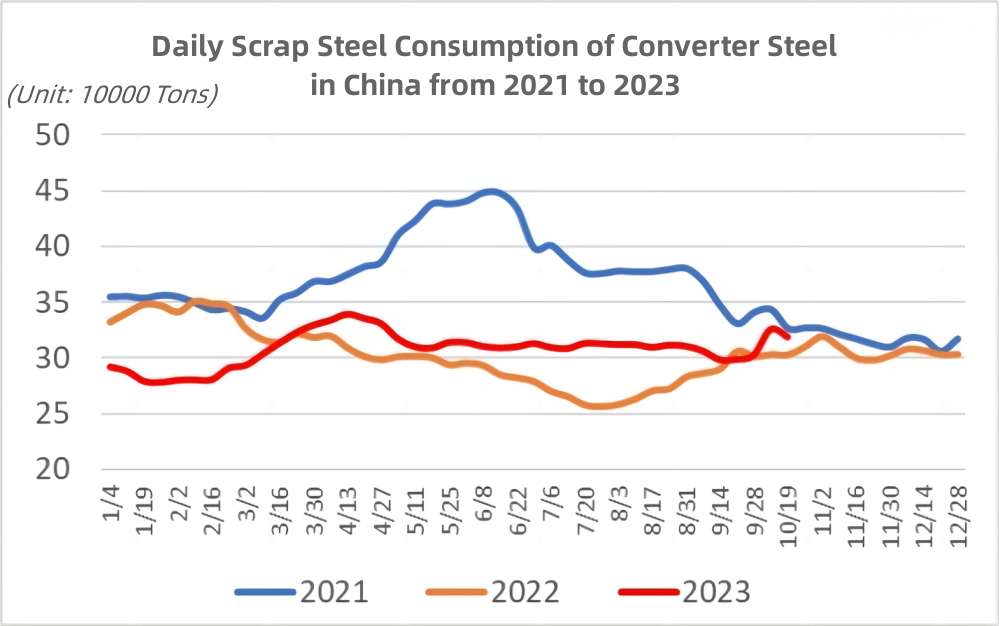

Due to the slow implementation of crude steel production control by steel mills in the third quarter and the unexpected increase in blast furnace capacity utilization, the current market faces significant pressure from resource supply. Under the influence of the continuous rise in iron ore and coke prices, long-process steel mills have significantly increased their losses, surpassing independent electric furnace steel mills. Recently, many enterprises in Yunnan, Shaanxi, and Shanxi have set clear production reduction targets, and many companies are adjusting their product structures toward flat products. This is good news for independent electric furnace steel mills. Follow us to continue exploring the production and sales trends in the steel market.

No related results found

0 Replies